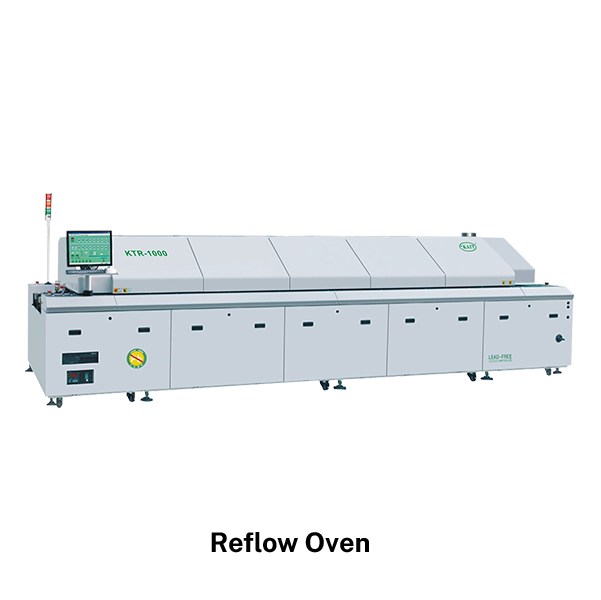

Brand: KAIT, China

REFLOW OVEN

- Meet various high-class requirements for lead-free reflow process

- Patent hot air system, using hot air convection conduction heat faster, more efficient compensation

- PLC+PID closed-loop control to achieve high precise temp. control and repeatable profiles

- Dual temp. sensors and dual safety control, the system shall cut off the power while abnormal case occurred

- Various alarm function: over temp. alarm, abnormal speed alarm, and PCB dropped alarm

- Modular design to get quick and simple maintenance so that reducing the maintenance time and cost

- The rail is dealt with the hardened process to make it more stability

- Perfect cooling effect with up 3 and bottom 3 cooling zones

- Adopted thick aluminium plate as rectifier of hot air, The ideal energy storage effect is obtained and the heating speed is faster

- Optional nitrogen system with oxygen concentration as low as 300ppm and nitrogen consumption as low as 10m3/hr

We’d love to help you boost your production efficiency. Contact us.

_Specifications_

| MODEL | TOP-1000 | TOP-1200 | TOP-1000D | TOP-1200D |

| HEATING SYSTEM PARAMETER | ||||

| Heating zones | Up 10/ bottom 10 | Up 12/bottom 12 | Up 10/bottom 10 | Up 12/bottom12 |

| Heating length | 3892mm | 5675mm | 3892mm | 4675mm |

| Cooling zones | Up 3/bottom 3 | |||

| Cooling system | Air cooling and optional water cooling system | |||

| Exhausting flow | 11-12 M³/min X 2 exhausting | |||

| CONVEYOR SYSTEM | ||||

| PCB max width | 400mm(option 460mm) | 300mmX2(single rail 50-450mm) | ||

| Rails structure | Overall sectional type | |||

| Chain structure | Double buckle for preventing pcb jammed | |||

| Conveyor direction | L-R(option R-L) | |||

| Fixed rail side | Front rail fixed(option back rail fixed) | 1/4 fixed and 2/3 moveable or 1/3 fixed and 2/4 moveable | ||

| Conveyor height | 900±20mm | |||

| PCB transporting | Chain+ melt(option chain+ center supporting system) | |||

| PCB height clearance | PCB up 30mm,bottom 30mm | |||

| Conveyor speed | 300-2000mm/min | |||

| Auto chain lubrication | Multi-lubrication mode can be chosen | |||

| CONTROL SYSTEM PARAMETER | ||||

| Power supply | 3PH,380V 50/60Hz(optional 3ph,220V 50/60Hz) | |||

| Total power | 80KW | 96KW | 83KW | 99KW |

| Starting up power | 36KW | 42KW | 38KW | 44KW |

| Working power | 10KW | 11KW | 11KW | 12KW |

| Warm-up time | Approx. 20 min. | |||

| Temp. control range | Room temp.—300C° | |||

| Temp. control mode | Closed loop PID controlled with SSR drive | |||

| Temp. control accuracy | ±1 C° | |||

| PCB temp. deviation | ±1.5C° | |||

| Data storage | Process data and status can be in storage | |||

| Abnormal alarm | Extra high and low temp. | |||

| Color tower | Yellow,red,green 3 color lamp | |||

| MACHINE PARAMETER | ||||

| Dimensions(LXWXH) | 6300X1430X1530 | 7050X1430X1530 | 6300X1680X1530 | 7050X1680X1530 |

| Weight | Approx.3020KG | Approx.3310KG | Approx.3060KG | Approx.3360KG |

| Color | Computer grey | |||

| Rectfying plate | thick aluminium plate | |||

| OPTION | ||||

| N2 configration | “-N”N2 config. With closed construction and pipe, flow meter, water chiller, oxygen analyzer | |||

| N2 consumption | Standard width machines(400mm): 300-1000PPM,10-20m³/hr; More big width machines(610mm): 500-1000PPM,25-30 m³/hr | |||

| Center supporting | Without melt | |||

Similar Products

_SMT Line Solutions_

SMT Reflow Ovens for Precision Soldering

Looking for a reliable SMT reflow machine to optimize your PCB assembly process? Our advanced SMT reflow ovens are designed to deliver precise temperature control, ensuring high-quality soldering for various electronic components. We offer advanced SMT reflow oven sourced from high-end manufacturers, ensuring enhanced efficiency and improved production yields.

Advanced Reflow Technology

Our reflow machines incorporate state-of-the-art heating zones, intelligent control systems, and energy-efficient designs to meet the demanding requirements of modern electronics manufacturing. Whether you need a compact model for small-scale production or a high-capacity SMT reflow oven for mass production, we have the perfect solution for your needs.

Trusted SMT Reflow Oven Manufacturers

Sourced from leading manufacturers, our SMT reflow oven offers cutting-edge technology to improve efficiency and production performance. Our products undergo rigorous testing to ensure consistent performance and reliability. Whether you are in consumer electronics, automotive, or medical device manufacturing, Kyoritsu’s SMT reflow machines provide the efficiency and precision you need.

Upgrade your production line with our cutting-edge reflow machines today! Contact us to learn more.