Brand : Essemtec, Archerfish, Switzerland

UNIQUE SOLUTION FOR ELECTRONIC PRODUCTION

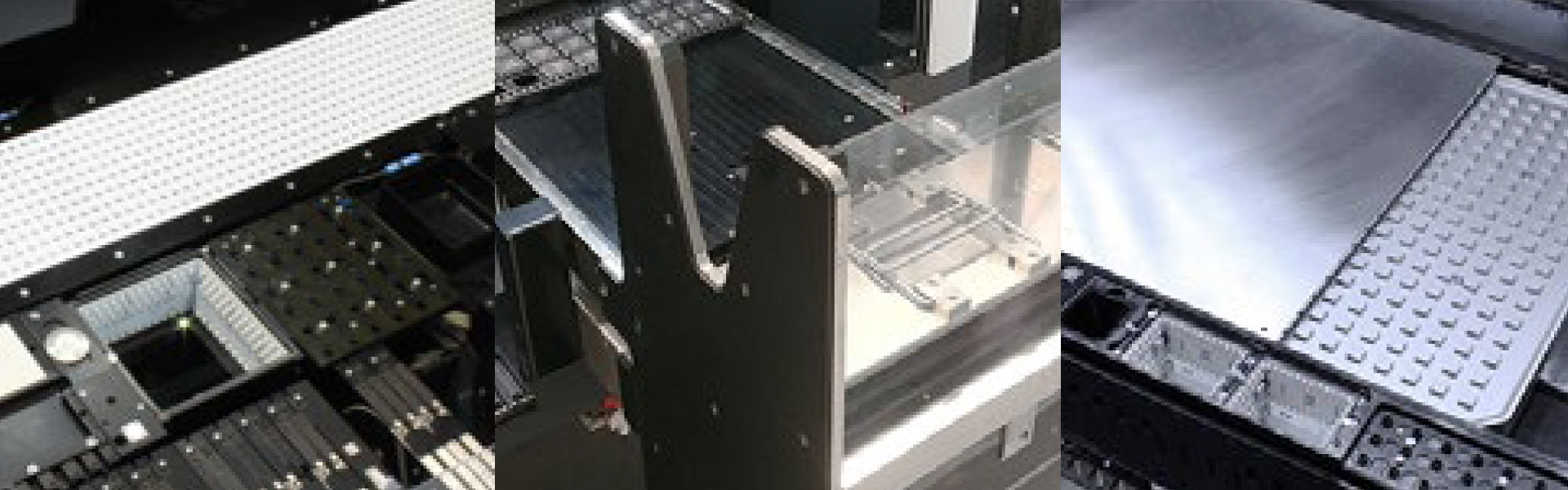

Precise and fast! Introducing the flexibility and scalability of PCB production on a minimal floorspace. By combining several processes on a single machine, hundreds of feeder options and a choice of valve options, you can quickly produce and test new electronic designs. Fastest time to market accelerates profitability in the industry through agile job changeover powered by our intuitive ePlace software.

Compatible With All Cost Optimization.

Advanced Essemtec

Platforms

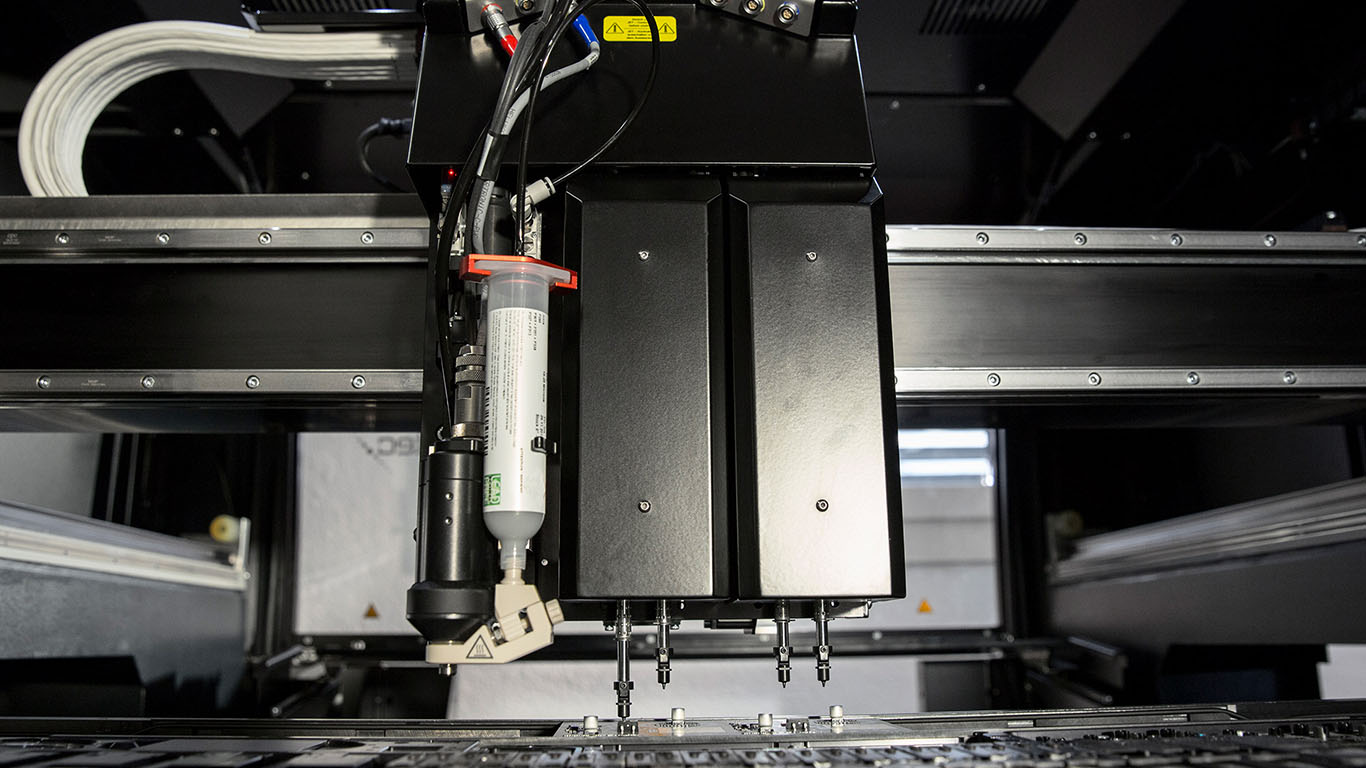

Combined Process

- Placement, solder paste & other jet dispensing

- Up to 4 placement-axes and 3 dispense processes

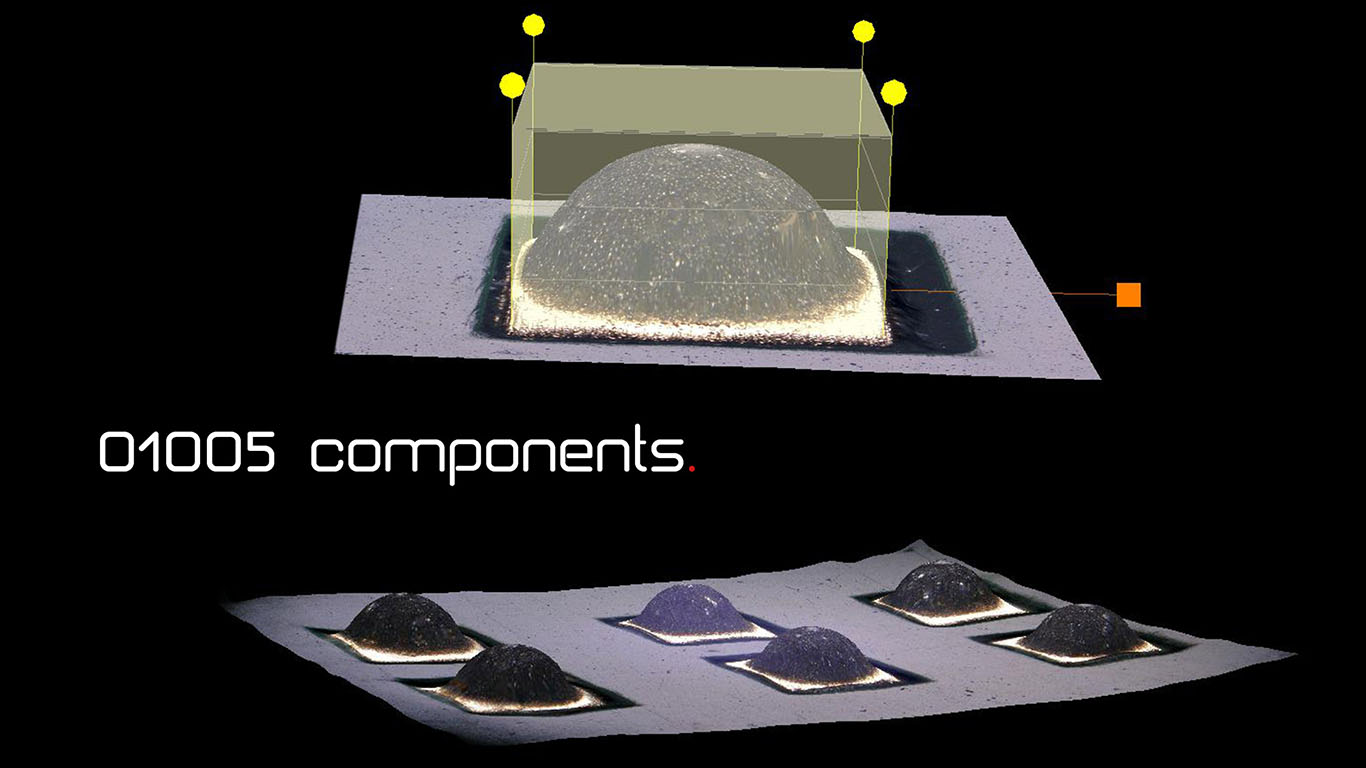

Process Control

- Monitoring sizes, volume & weight of jetted dots

- Process control adjustment and dot stabilisation

Cost Optimization

- One space saving platform.

- Decrease of costs (no additional printer or stencils)

- Zero changeover time

Highest Flexibility

- Improve time to market/ NPI/ Immediate repair

- No waiting for stencil, process variation adaptation

- Jetting in cavities, Pin in paste jetting

- PCB design freedom - all programmable

- 2.5D placement and dispensing applications

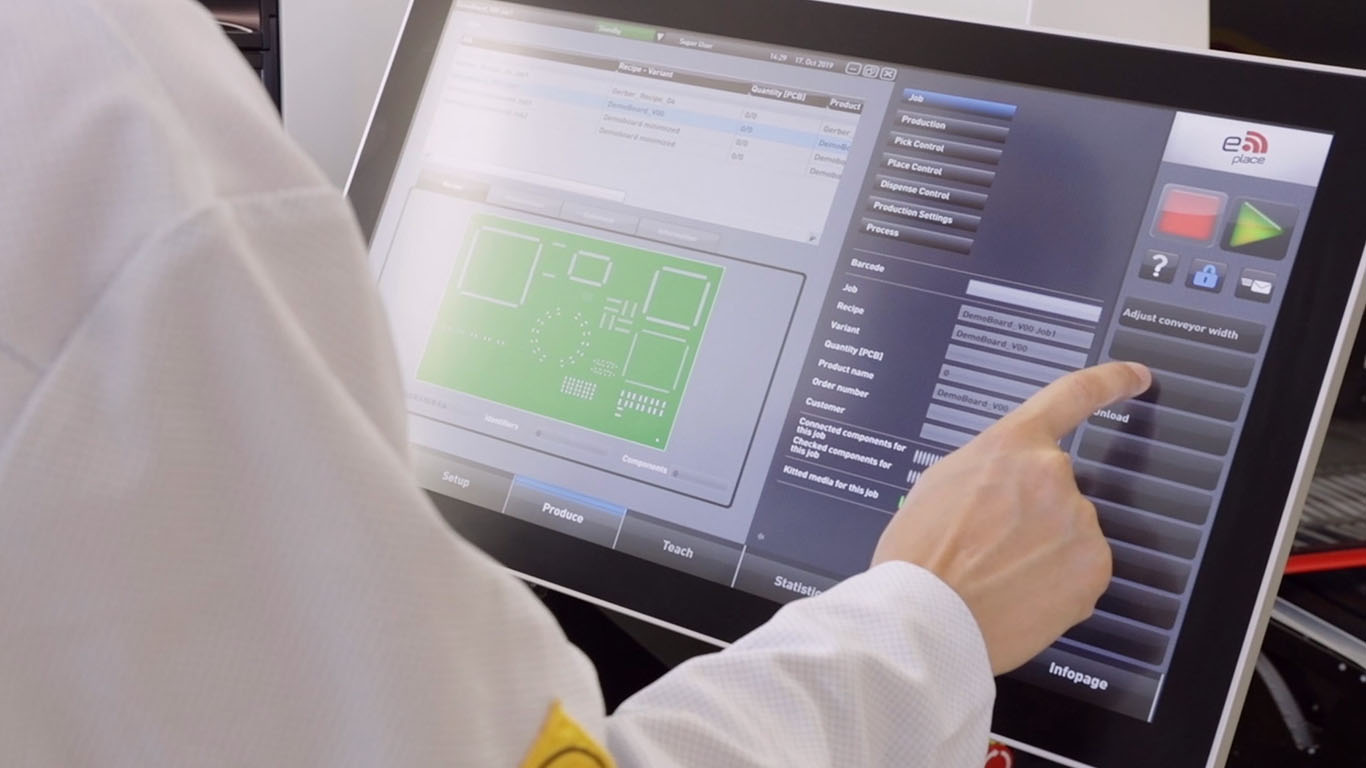

Software For All Processes.

- Gerber file conversion and CAD data import

- One click production file generator

- Real time visualisation

- Connectivity SECS/GEM, iTac, OIC, Hermes

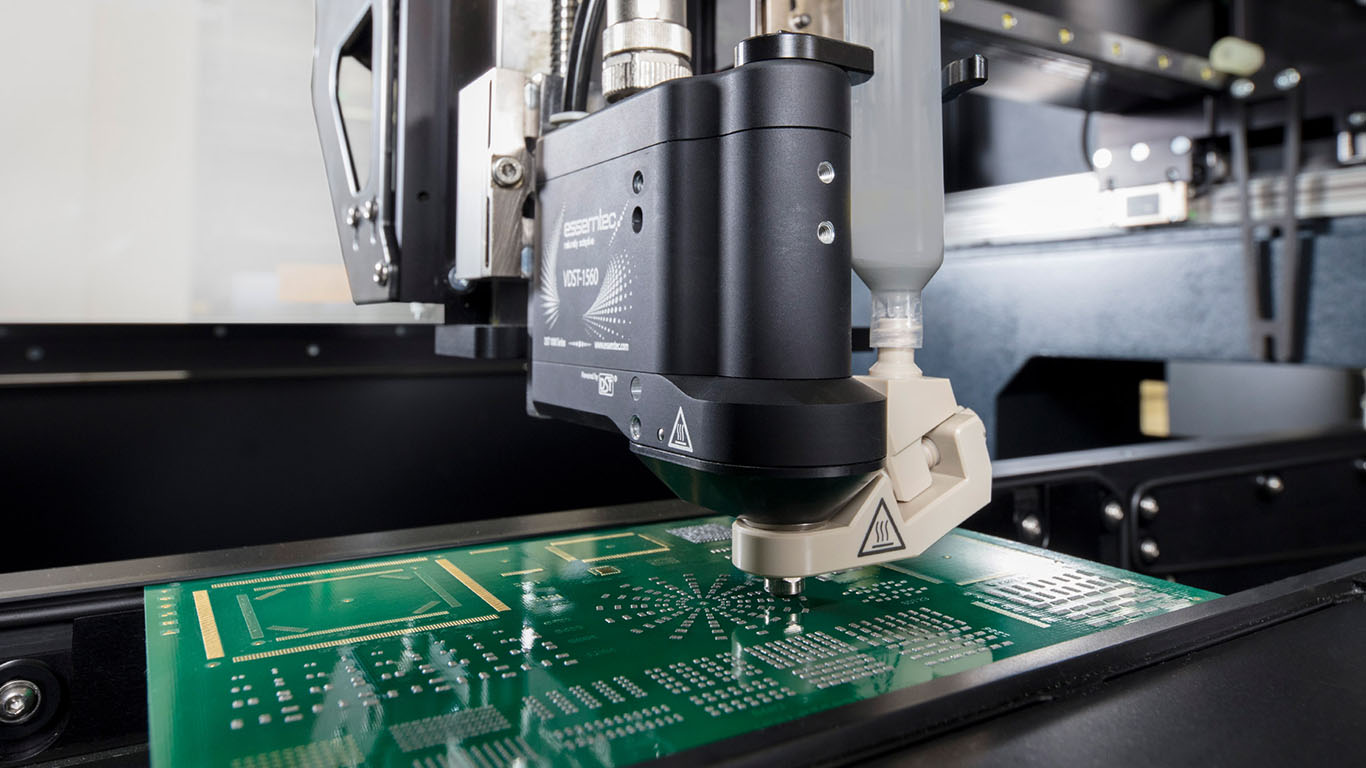

Essemtec Archerfish SMT Pick & Place System

_Specifications_

| Pick and Place | puma2 (up to 2 valves) | puma4 (up to 1 valve) | fox2 (up to 1 valve) |

|---|---|---|---|

| Optimal placement speed | 11’200 cph (2-axes) | 18’100 cph (4-axes) | 12’000 cph (2-axes) |

| Feeder capacity 8 mm tape | 260 (140 inline) | 280 (160 inline) | 180 (120 inline) |

| Component size range | 008004 (imp.) up to 80 x 80 mm (Note specs for details) | ||

| Placement accuracy (x, y) | Chip ± 40 μm (3σ) / QFP ± 30 μm (3σ) | ||

| Max. PCB dimensions | 560 x 610 / 1’800 x 610 mm | 560 x 610 / 1’800 x 610 mm | 406 x 305 mm |

| Machine footprint | 1’557 x 1’357 mm (61 x 53“) | 1’557 x 1’357 mm (61 x 53“) | 880 x 1’090 mm (34.7 x 43“) |

| solder paste jet printing | |||

|---|---|---|---|

| Viscosity range | < 2’000’000 mPa*s | ||

| Min. possible dot Ø / volume | >200 µm / > 2.5 nl | ||

| Optimum speed | Up to 80’000 dots/h | ||

| Useable solder pastes | Type 4-7 ( jettable) | ||

| Valve heater | Included, max. 60°C | ||

| Useable cartridge sizes | 5 ccm / 10 ccm / 30 ccm | ||

| dispensing | |||

|---|---|---|---|

| Optimum speed (dots/h) |

Glue Jet: 150’000 Time-Pressure: 28’000 Volume: 24’000 Screw: 24’000 |

||

| Dispense mode |

Dot, line, curve, interpolated 2.5D contour |

||

| Placement XY dots | 40 μm (3σ) | ||

We’d love to help you boost your production efficiency.

Contact us.

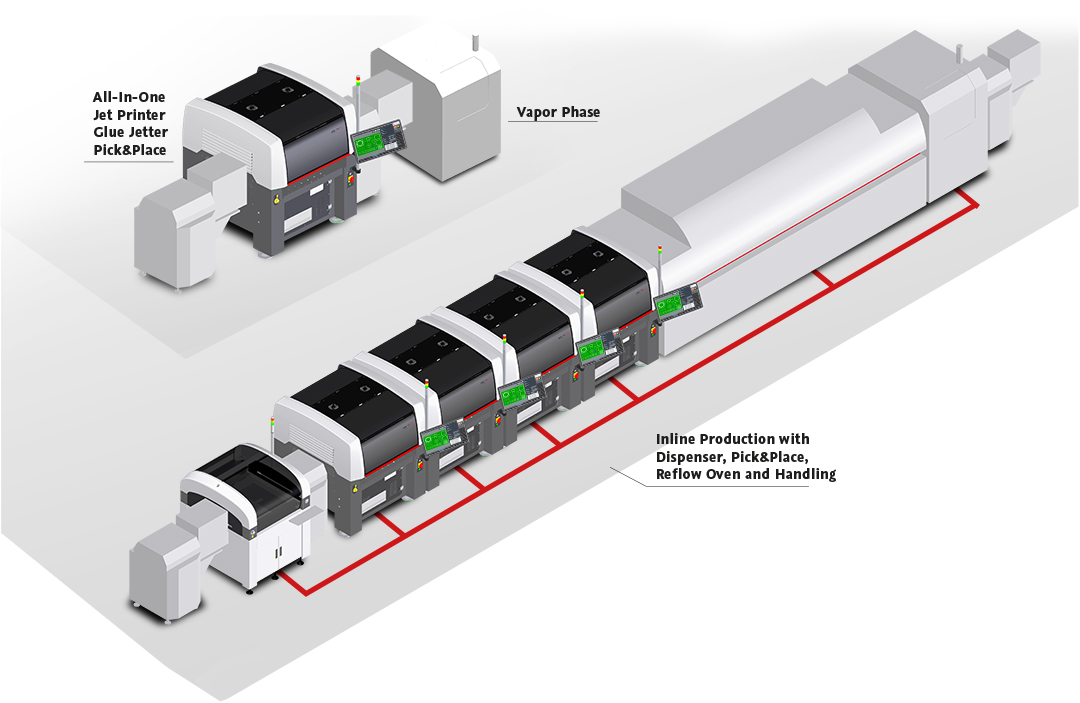

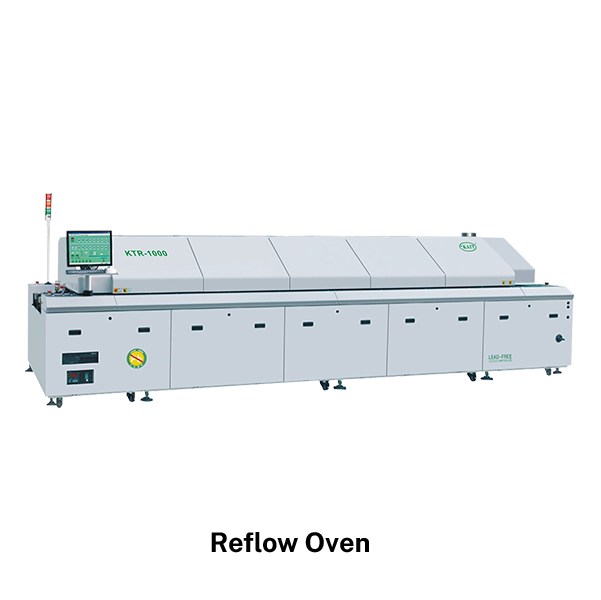

Expansion In Any Direction. Adaptive From Prototyping

To High Speed Production.

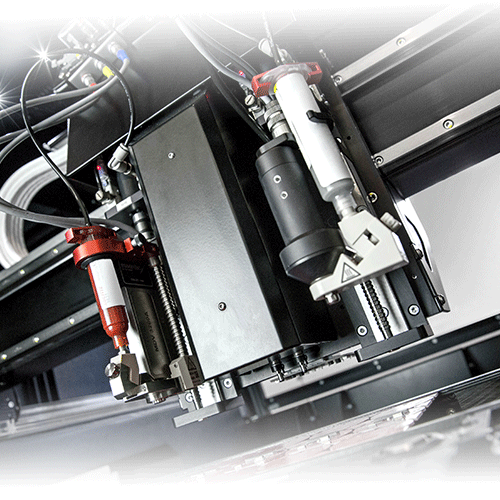

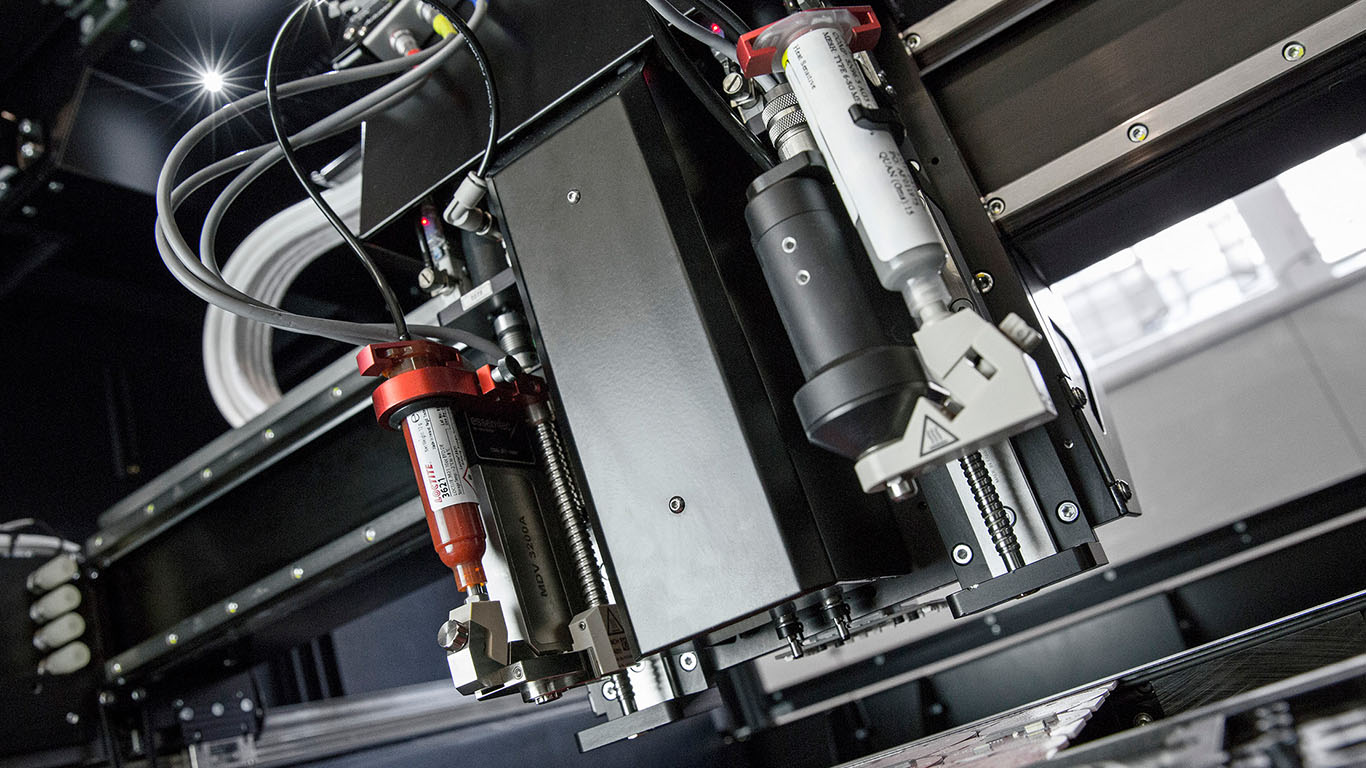

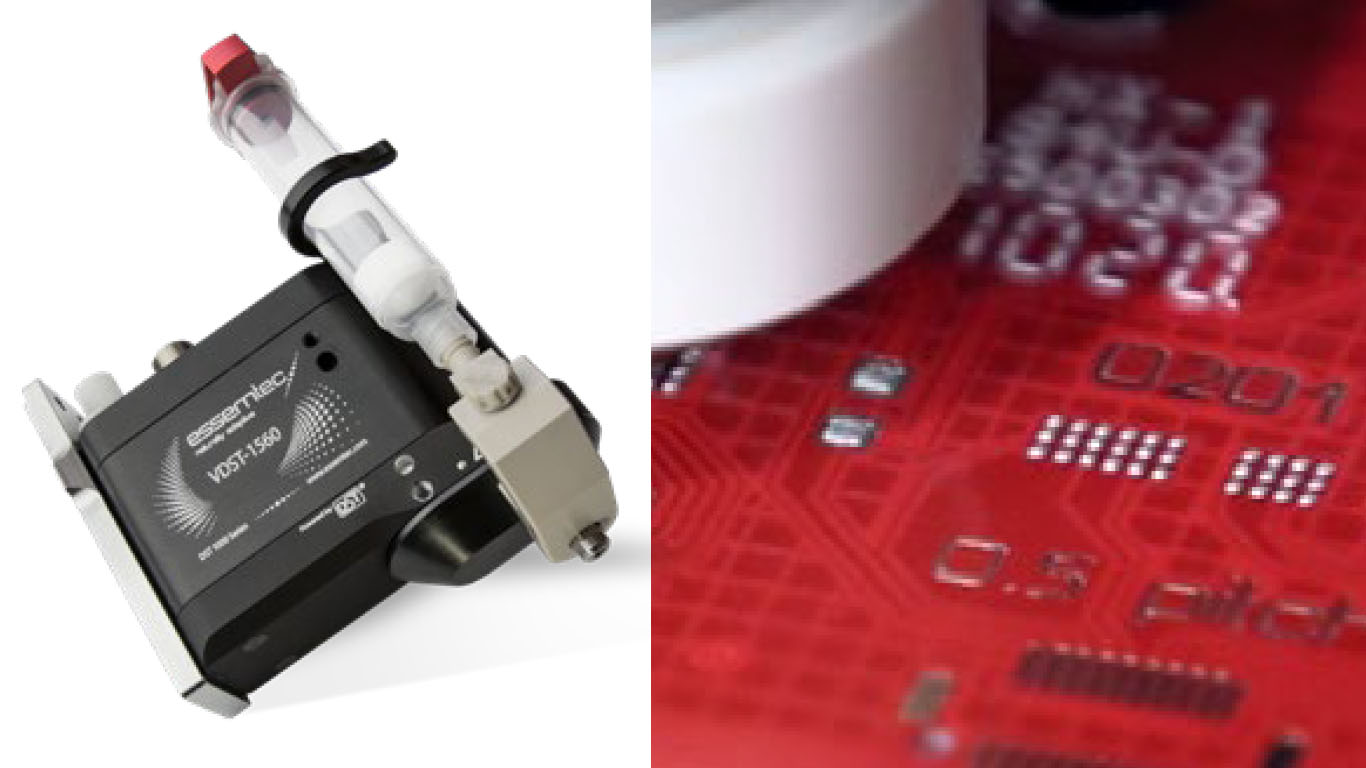

Solder Paste Jet Printing

Dynamic Shockwave Technology. Adaptable for different jettable pastes (T4-7). Adaptable for special applications (nozzle, tappet, temperature etc.). Adaptable with needles for deep cavities. Super fast Plug n‘ Play change of fluidic and settings.

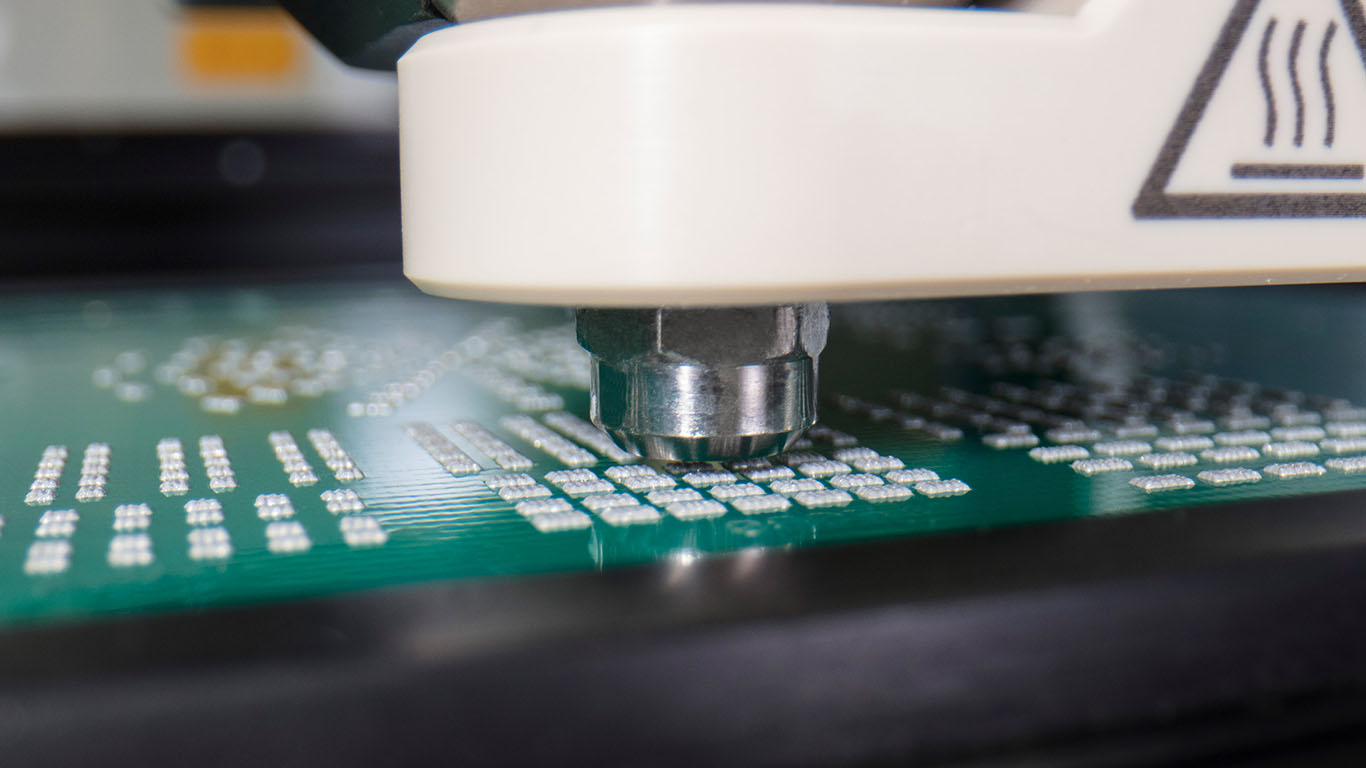

Pick and Place

Dynamic Shockwave Technology. Adaptable for different jettable pastes (T4-7). Adaptable for special applications (nozzle, tappet, temperature etc.). Adaptable with needles for deep cavities. Super fast Plug n‘ Play change of fluidic and settings.

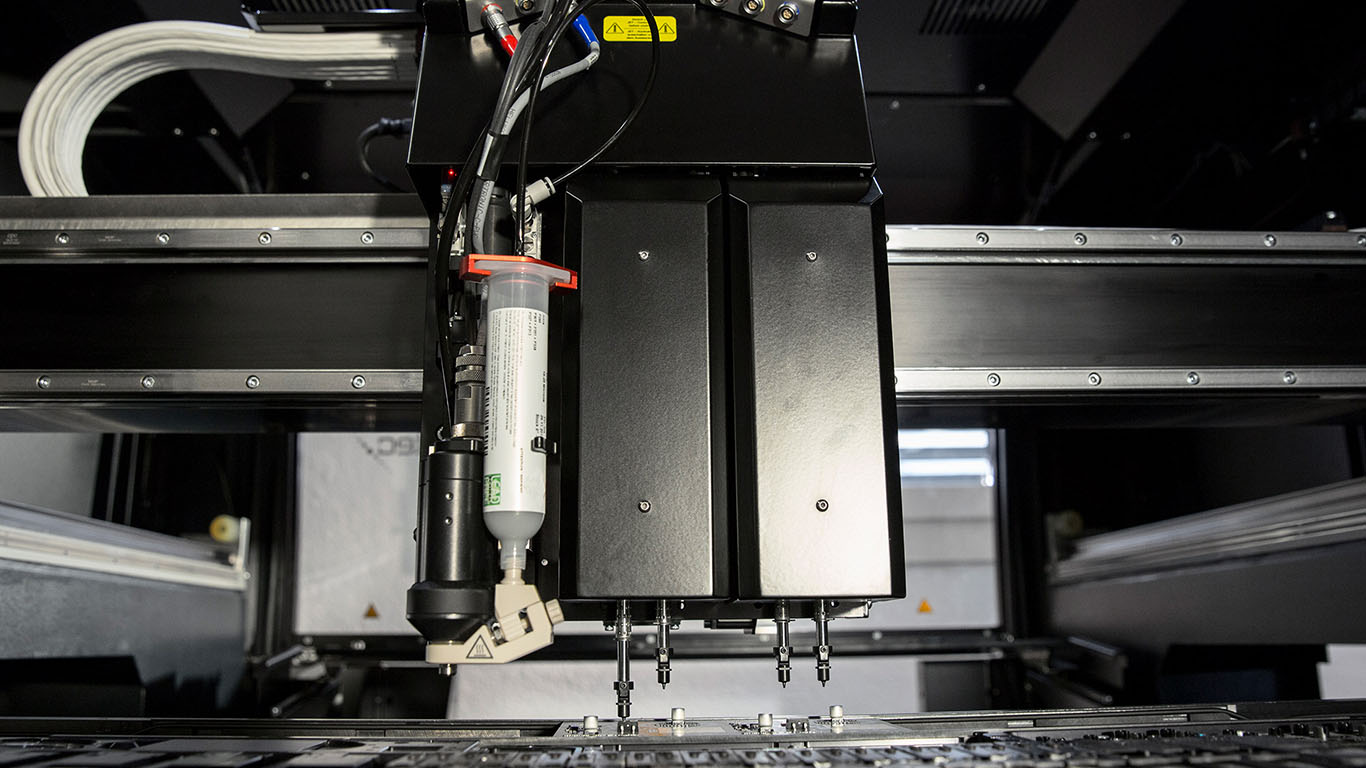

Other Dispensing Solutions

Wide range of dispensing applications such as SMT Glue, LED Encapsulation, Silver Epoxy, Dam and Fill, Underfill, Cavity Fill, 2.5D dispensing and more. Process parameters can be changed freely and optimized for any particular process.

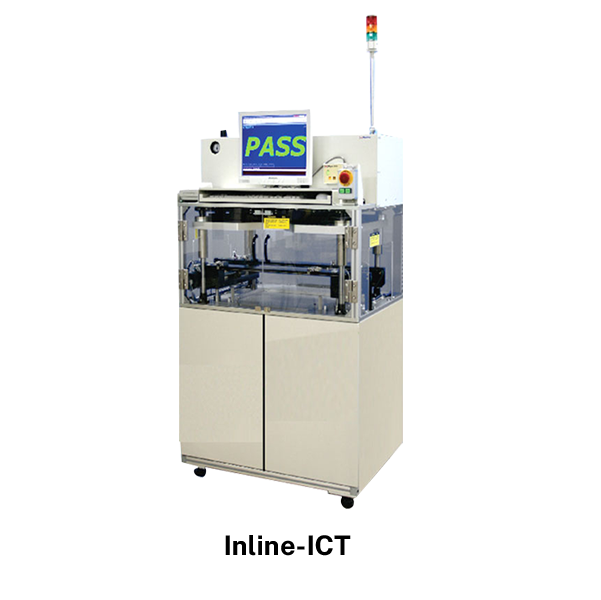

Full process control & traceabilty meeting automotive standards, Adaptation & stabilisation, Integration & datatransfer of existing pick&place machines as Diplan, UniCam, Cogiscan etc., Cleaning Station, High Precision Scale, Heat-/Vacuum Tables

Media Heating - Needle and jet heating system

Level Detection - Automatic syringe level detection

Tray Slider/ Changer - Unique system to increase the amount of trays

Increase Boardsize - Table extension to increase the processable board size