Optional Equipment for your Processes

Videos

Pick-and-Place

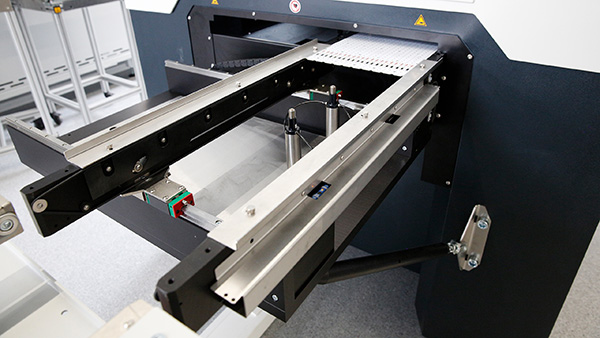

Automatic Tray Slider

Automatic tray slider for up to 2 additional trays. The main advantage means there is no loss of feeder space and maximum board size. The tray slider is installed "free floating" above the regular feeders on the back of the machine. The positions are freely programmable.

Available for Puma, Fox

Automatic Tray Changer

Automatic tray changer for up to 18 standard JEDEC trays. The tray changer is the flexible feeding solution for different tray components. Possibility of tray exchange as well as filling-up the empty trays during running production.

Available for Puma, Fox

Component Verification Unit

Measure / Verify diodes and LCR Properties of components. The CVU is used for a value check of a component before being placed on a pcb. A fully integration into the pick and place process is provided within two modes. Following SMD components (2-pins) can be measured: Resistors, Capacitors, Inductors, Diode polarity.

Available for Puma, Fox

Longboard for 1.8 m PCB`s

The Longboard Option allows handling of special long PCB`s of up to 1`800 mm length. Those boards are usually to be found in LED applications and products. There exist three different lengths: 1.2 m / 1.5 m / 1.8 m. All conveyor motors are closed loop controlled and equipped with an encoder. Special extensions are mounted on the conveyor, so that a proper clamping of the whole PCB is guaranteed.

Available for Puma, Fox

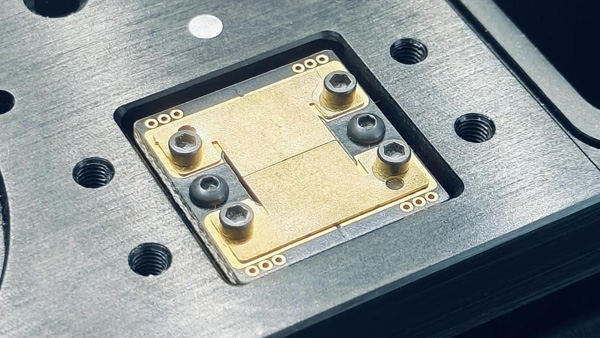

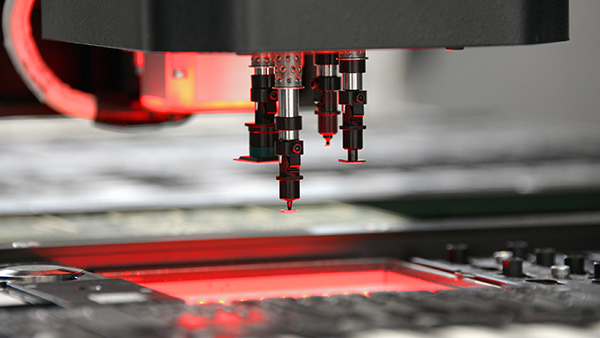

Dipping Station

The dipping station expands the application range of the pick and place system FOX and PUMA. With this module its possible to dip BGA style components into a media (usually flux) and place it onto the PCB. It`s mostly used for small BGA packages. The exact deepness of dipping is guaranteed by high precision cavities, into which the packages are dipped.

Available for Puma, Fox

Dispensing

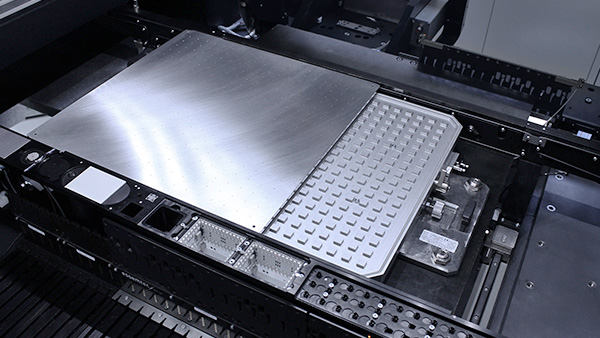

Vacuum Tables

Handling solution for Pick and Place and Dispensers to process very thin PCB`s and foils, using a carrier and a large area vacuum table. The PCB`s or foils are previously placed on an aluminum carrier. The carriers are then transported by the conveyor and loaded into the machine, like a normal PCB. Complete vacuum table is removable within a minute, all connections are designed as quick connect/disconnect.

Available for Puma, Fox, Tarantula, Spider

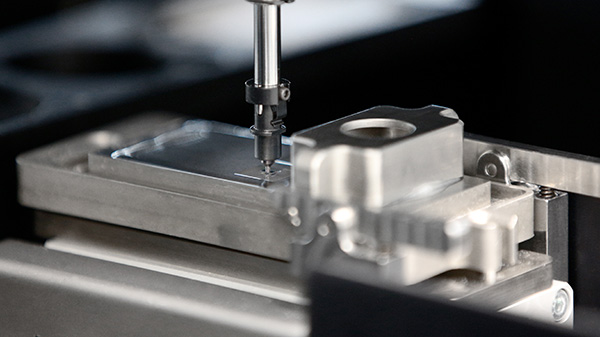

Dispensing Valves

Contact and/ or Non-contact jetting dispensing valves can be used for typical solder pastes, glues and a wide range of liquid materials from low to high viscosity. Especially sensitive fluids with high viscosity and fillers inside experience a gentle treatment due to the low shear stress and the low pressure. The valve configuration (valve seat, heaters and nozzle) need to be defined according to the application and used medium.

Available for Puma, Fox, Tarantula, Spider

Software

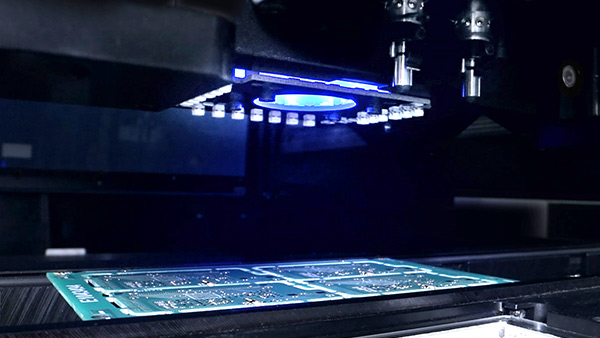

I2S - Integrated Inspection

The Integrated Inspection System is available for inspection of dispensed and jetted material as well as placed SMD components right after the process, to ensure only good, inspected products are entering the reflow ovens. The process also includes an automated repair function. The system is already integrated in automotive and complex production sites.

Available for all Machines with ePlace Software

IPC-CFX-2591

CFX (Connected Factory Exchange) is an industry-developed open international standard forming the foundation of «Factory of the Future» applications. ePlace supports all mandatory capabilities of the IPC-CFX SMT Mounter (Pick and Place) endpoint class, as well as a subset of relevant optional transactions. This enables MES and ERP systems to acquire machine description, performance, recipe visibility, WIP tracking and traceability data, among others.

Available for all Machines with ePlace Software

IPC-HERMES-9852

The Hermes Standard is an open protocol based on TCP/IP- and XML. It defines the horizontal connection from machine to machine (M2M). Idea is to replace the antiquated hard wired SMEMA interface by a messaging system over the mostly anyway existing ethernet network.

Available for all Machines with ePlace Software

KEY PERFORMANCE INDICATORS

One of the first common questions about a machine is the speed. How many components can be placed per hour? How many dots can be dispensed per hour? The KPI software module helps to ask the right questions from the beginning. It is integrated into ePlace and can get used directly on the machine or on an offline station.

Available for all Machines with ePlace Software

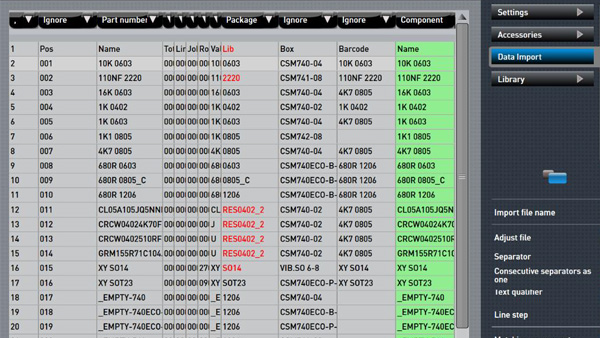

Setup Check and Traceability

Three simple checks ensure that the production runs correctly and that the operator can no longer make mistakes. All relevant data is tracked and can be accessed and analyzed offline at any time.

Available for all Machines with ePlace Software

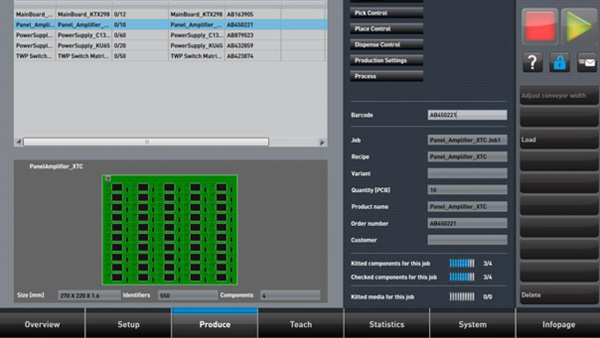

Load Job with Barcode

In ePlace and eMis a job can get loaded by reading a barcode. Use the barcode field in Setup and Produce tab to scan a barcode e.g. from a production sheet. The read barcode has to be equal to the job name or order number of an existing job and it has to be unique.

Available for all Machines with ePlace Software

Data Export from Placer Software to ePlace

Customers upgrading their machine platforms running with Placer software on FLX / PAN X / PANTERA or LYNX have the possibility to export their component library and CAD data into the new ePlace software.

Kyoritsu together with Essemtec can give support for this procedure.

Available for all Machines with ePlace Software

PICK AND PLACE SPEED-UP

With ePlace version 23 or higher, the production cycle for the existing pick and place machines Cobra and Paraquda is further optimized. The speed-up is reached by eliminating waiting times during the production cycle and by improved "3D-moves". Axis speeds and accelerations will remain the same as before.

Available for all Machines with ePlace Software