Brand: ELITE, Taiwan

INLINE ROUTER

Model: ER-6000-AT

- Gantry structure increase cutting accuracy and cutting speed

- Extended router bits life by multistage auto compensation of Z height to reduce cost

- Integrated shell and safety door sensor fit for public safety demand

- Using a working table to push the PCB panel margin into the trash bucket which is in front of the router to reduce equipment placement space

We’d love to help you boost your production efficiency. Contact us.

_Specifications_

| PCB Size (mm) | SW: 330X420 |

| DW: 400X420 | |

| DX: 500X500 | |

| Cutting speed | 1~100mm/s |

| XY Repeatability | ±0.02mm |

| Contrl System | PC based 6 axis controller |

| XYZA driving | AC servo motor |

| Cutting Accuracy | ±0.1mm |

| Spindle rotation | Max 60000rpm |

| Power Supply | 1ɸ, AC 220V 50/60Hz |

| Air Supply | 4~6 kg/cm², flow: 1500L/hr |

| Power Consumption | 3KVA |

| Conveyor Height | 920±20mm |

| Dust collector | 3HP external, bottom suction |

| Power supply of dust collector | 220V (380V)3ɸ |

| Router Dimension (WXDXH mm) | SW: 1812X1510X1730 |

| DW: 2052X1560X1733 | |

| DX: 2450X1720X1710 | |

| Weight (Kg) | SW: 780 |

| DW: 880 | |

| DX: 1150 |

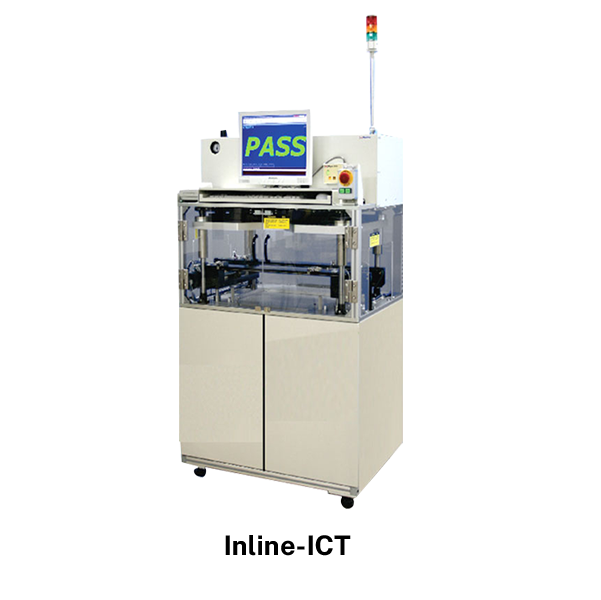

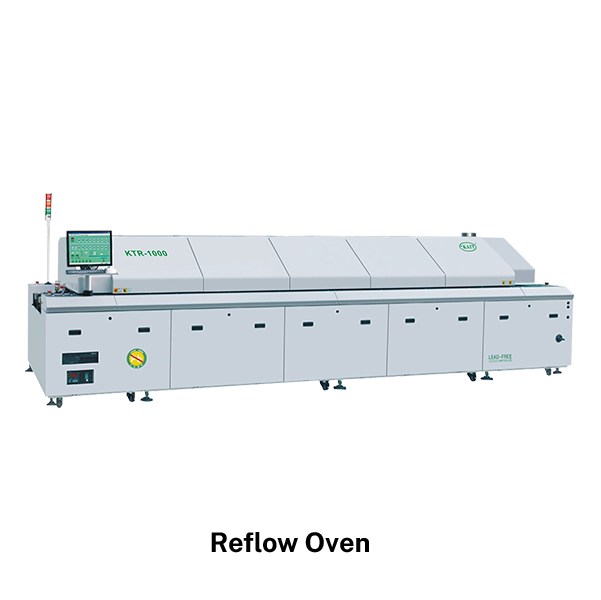

Similar Products

_SMT Line Solutions_

Inline PCB router machines have emerged as a revolutionary solution for PCB depaneling, offering precise and efficient separation of printed circuit boards. These machines are designed to streamline the manufacturing process by automating the intricate task of separating individual PCBs from larger panels, enhancing productivity and reducing production costs.

The Inline PCB router machine is equipped with advanced cutting-edge technology and features that ensure accurate and clean separation of PCBs. With their high-speed spindles and precision control systems, these routers can effortlessly cut through the board material, such as FR-4 or aluminum, without causing any damage to the delicate components or the circuit traces.

One of the key advantages of an Inline PCB router machine is its inline configuration. Unlike traditional routers that require manual intervention and handling of panels, these machines can be integrated seamlessly into the production line, allowing for continuous and uninterrupted PCB depaneling. The inline setup eliminates the need for extra handling steps, reducing the risk of errors and enhancing the overall efficiency of the manufacturing process.

The inline router machines for PCB depaneling offer versatility in terms of panel sizes and shapes they can handle. Whether it's rectangular, circular, or irregular-shaped panels, the machine's adjustable fixtures and customizable cutting paths enable precise and reliable depaneling for a wide range of PCB designs. This flexibility makes them suitable for various industries, including electronics, automotive, telecommunications, and medical devices.

Moreover, inline PCB router machines incorporate safety features to protect operators and prevent damage to the equipment.