Brand: IBL, Germany

MiniLab

- Automated table top reflow soldering machine in which the heat is transferred by condensing vapour

- Ideal for development, prototyping, rework and mini series production

- Patented flash-lock to process chamber while loading and unloading

- Program memory up to 16 programs

We’d love to help you boost your production efficiency.

Contact us.

_Specifications_

Technical data |

MiniLab |

Width |

715 mm (28.15“) |

Depth |

625 mm (24.61“) |

Height |

580 mm (22.83“) |

Weight |

70 kg (154.32 lbs) |

Max. PCB size |

304 x 274 x 80 mm (11.97 x 10.79 x 3.14“) |

Max. load on single carrier |

2 kg (4,41 lbs) |

Liquid agent filling |

3 kg (6,61 lbs) |

Water connection |

½“ / |

Max. heating capacity |

1,8 kW |

Average power consumption |

0,8 kW/h |

Brand: IBL, Germany

SV260

- Table top unit with easy front loading

- Optimized for laboratory operation, prototyping, rework and small series production

- Low energy and fluid consumption with 2-chamber design and integrated heat exchanger

- Easy operation, solder automatic, program storage

- Live temperature monitoring without high temperature profiler

- Maintenance-free transport system (patented)

We’d love to help you boost your production efficiency.

Contact us.

_Specifications_

Technical data |

SV 260 |

Max. PCB size |

260 x 300 x 70 mm (10.24 x 11.81 x 2.76“) |

L x D x H |

770 mm x 710 mm x 680 mm |

Weight |

110 kg (242.51 lbs) |

Max. load on single carrier |

2,5 kg (5,51 lbs) |

Liquid agent filling |

3 kg (6,61 lbs) |

Water connection |

½“ / |

Max. heating capacity |

2,1 kW |

Average power consumption |

0,9 kW/h |

Brand: IBL, Germany

SV540

- Powerful unit for single and series production

- Small footprint designed for prototyping and small series production, and masters the soldering of BGAs and LGAs.

- Low energy and fluid consumption with 2-chamber design and integrated heat exchanger

- Touch panel for easy operation, solder automatic, program storage

- TE-Option with 2 temperature measuring channels for thermal profile monitoring and recording

We’d love to help you boost your production efficiency.

Contact us.

_Specifications_

Technical data |

SV 540 |

Max. PCB size |

540 x 360 x 85 mm (21.26 x 41.17 x 3.35“) |

L x D x H |

1450 mm x 800 mm x 1400 mm |

Weight |

340 kg (lbs) |

Max. load on single carrier |

3 kg (6.61 lbs) |

Liquid agent filling |

13 kg (28.66 lbs) |

Max. heating capacity |

5,2 kW |

Average power consumption |

2,8 kW/h |

Brand: IBL, Germany

BLC 420

- New Design with small footprints & low power consumption

- Cost-saving due to the 2-chamber design and medium recovery

- Innovative because of the big touch -screen monitor with new and easy handling software

- Available as batch or inline the machine is perfect for medium to high volume production

- The system promises oxygen-free soldering and no overheating of components

- Maximum solder quality and flexibility are provided by countless patented functions

We’d love to help you boost your production efficiency.

Contact us.

_Specifications_

|

BLC620i |

BLC820i |

Max. PCB size inline modus |

630 x 400 x 55 mm (24.80 x 15.75 x 2.17“) |

630 x 400 x 55 mm (24.80 x 15.75 x 2.17“) |

L x D x H |

2020 mm x 2490 mm x 1470 mm |

2220 mm x 2490 mm x 1470 mm |

Weight |

920 kg (2028.25 lbs) |

1070 kg (2358.95 lbs) |

Max. PCB size batch modus |

650 x 540 x 80mm (25.59 x 21.26 x 3.15”) |

850 x 540 x 80mm (33.46 x 21.26 x 3.15”) |

Max. PCB size |

650 x 540 x 80 mm |

850 x 540 x 80 mm |

Max. load on single carrier |

7 kg (15.43 lbs) |

7 kg (15.43 lbs) |

Liquid agent filling |

20 kg (44.10 lbs) |

25 kg (55.12 lbs) |

Water connection |

½” / 2,5 – 5 bar |

|

Max. heating capacity |

2020 mm x 2490 mm x 1470 mm |

2220 mm x 2490 mm x 1470 mm |

Average power consumption |

3,2 kW/h |

3,6 kW |

Max. heating capacity |

7,8 kW |

10,4kW |

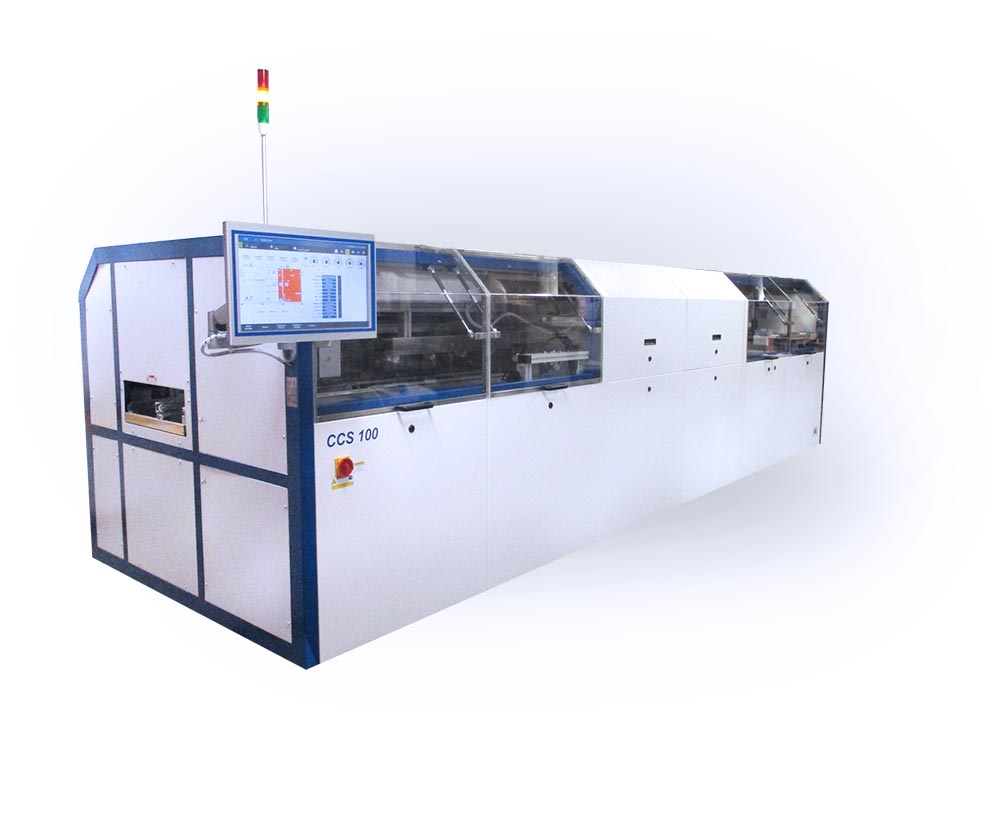

CCS100

- Multiple-carrier system with variabel lane configuration of the work piece carriers

- Work piece carrier return transport

- Modular design, multi-zone construction with upstream buffer and downstream cooling zone

- Powerful bottom cooling for board cooling after the soldering process

- Efficient Maintenance System with Galden levelling and filtering system

- Maintenance-friendly design

- Heat exchanger systems for efficient fluid recovery

- Automatic lane width adjustment of the conveyor systems

- Automatic loading and unloading of the boards

We’d love to help you boost your production efficiency.

Contact us.

_Specifications_

| CCS100 | |

| Length | 5820 mm |

| Depth | 1800 mm |

| Height 1670 mm | 1670 mm |

| Fixed cheek 805 mm | 805 mm |

| Weight 2000 kg | 2000 kg |

| Usable PCB format , length | 80 – 1000mm |

| Usable PCB format , width (work piece carrier without mid support) | 50 – 500mm |

| Usable PCB format , width (work piece carrier with mid support) | 100 – 500mm |

| Edge support PCBs | 3 mm (6 mm with HD-Option) |

| Standard fluid filling amount (Galden) | 60 kg |

| Power supply | 400/230 VAC 50/60 Hz 3 Phases, Neutral and PE |

| Connecting power | 9 kW |

| Max. heating power | 7 kW |

| Average power consumption | 5,6 kW/h |

| Protection / circuit breaker | 25A „gl“ or „C“ |

| Water supply | ½“ 2,5 – 5 bar |

| Exhaust connections | 2 x ø150mm |

BLC Inline

- Comfortable 15” Touch-Screen mounted on a swiveling arm

- Integrated PC, allows permanent data collection and professional data management

- Permanent data collection

- Unlimited program memory with a large amount of sample programs

- Network capable

- Password protected operation levels

- Energy management system

- Intelligent Profiling System (IPS) for high-end thermal profile control

- Buffer in the loading and unloading areas

- Automatic loading and unloading Work Piece Carrier

- Signal light tower

- Patented vibration and maintenance free transport system

We’d love to help you boost your production efficiency.

Contact us.

_Specifications_

| BLC620i | BLC820i | |

| Width | 2020 mm (75.73“) | 2220mm (87.40“) |

| Depth | 2490 mm (98.03“) | 2490 mm (98.03“) |

| Height | 1470 mm (57.87“) | 1470 mm (57.87“) |

| Weight | 920 kg (2028.25 lbs) | 1070 kg (2358.95 lbs) |

| Max. PCB size inline modus | 630 x 400 x 55 mm (24.80 x 15.75 x 2.17“) | 630 x 400 x 55 mm (24.80 x 15.75 x 2.17“) |

| Max. PCB size batch modus | 650 x 540 x 80mm (25.59 x 21.26 x 3.15”) | 850 x 540 x 80mm (33.46 x 21.26 x 3.15”) |

| Max. load on single carrier | 7 kg (15.43 lbs) | 7 kg (15.43 lbs) |

| Liquid agent filling | 20 kg (40.10 lbs) | 25 kg (55.12“) |

| Water connection | ½” / 2,5 – 5 bar | ½” / 2,5 – 5 bar |

| Max. heating capacity | 7,8 kW | 10,4kW |

| Average power consumption | 3,2 kW/h | 3,6 kW/h |

| Power supply | 400 / 230 VAC, 50/60Hz | 400 / 230 VAC, 50/60Hz |

| Main fuse | 20A „gl“ or „C“ | 32A „gl“ or „C“ |

VAC Inline

- Comfortable 15” Touch-Screen mounted on a swiveling arm

- Integrated PC, allows permanent data collection and professional data management

- Permanent data collection

- Unlimited program memory with a large amount of sample programs

- Network capable

- Password protected operation levels

- Heating power monitoring

- Energy management system

- Intelligent Profiling System (IPS) for high-end thermal profile control

- Buffer in the loading and unloading areas

- Automatic loading and unloading Work Piece Carrier

- Patented vibration and maintenance free transport system

We’d love to help you boost your production efficiency.

Contact us.

_Specifications_

| VAC745i | VAC765i | |

| Width | 2040 mm - (80,31“) | 2040 mm - (80,31“) |

| Depth | 3040 mm – (119.69“) | 3450 mm – (135.83“) |

| Height | 1470 mm - (57.87“) | 1470 mm - (57.87“) |

| Weight | 1290 kg (2843.96 lbs) | 1450 kg (3196.70 lbs) |

| Max. PCB size inline modus | 630 x 400 x 50 mm (24.80 x 15.75 x 1.97”) with vacuum | 630 x 400 x 60 mm (24.80 x 15.75 x 2.36”) without vacuum |

| Max. PCB size batch modus | 635 x 444 x 70 (25.00 x 17.48 x 2.76”) with vacuum 635 x 444 x 80 mm (25.00 x 17.48 x 3.15”) without vacuum | 635 x 644 x 70 mm (25.00 x 35.35 x 2.76”) with vacuum 635 x 644 x 80 mm (25.00 x 25.35 x 3.15”) without vacuum |

| Max. load on single carrier | 7 kg (15.43 lbs) | 7 kg (15.43 lbs) |

| Liquid agent filling | 40 kg (88.18 lbs) | 60 kg (132.28 lbs) |

| Water connection | ½” / 2,5 – 5 bar | ½” / 2,5 – 5 bar |

| Max. heating capacity | 10,4 kW | 13kW |

| Average power consumption | 5,5 kW/h | 5,8 kW/h |

| Power supply | 400 / 230 VAC, 50/60Hz | 400 / 230 VAC, 50/60Hz |

| Main fuse | 32A „gl“ or „C“ | 32A „gl“ or „C“ |

| External vacuum module | 910 x 550 x 650mm (35.83 x 21.65 x 25.59“), 119 kg (262.35 lbs) | 910 x 550 x 650mm (35.83 x 21.65 x 25.59“), 119 kg (262.35 lbs) |

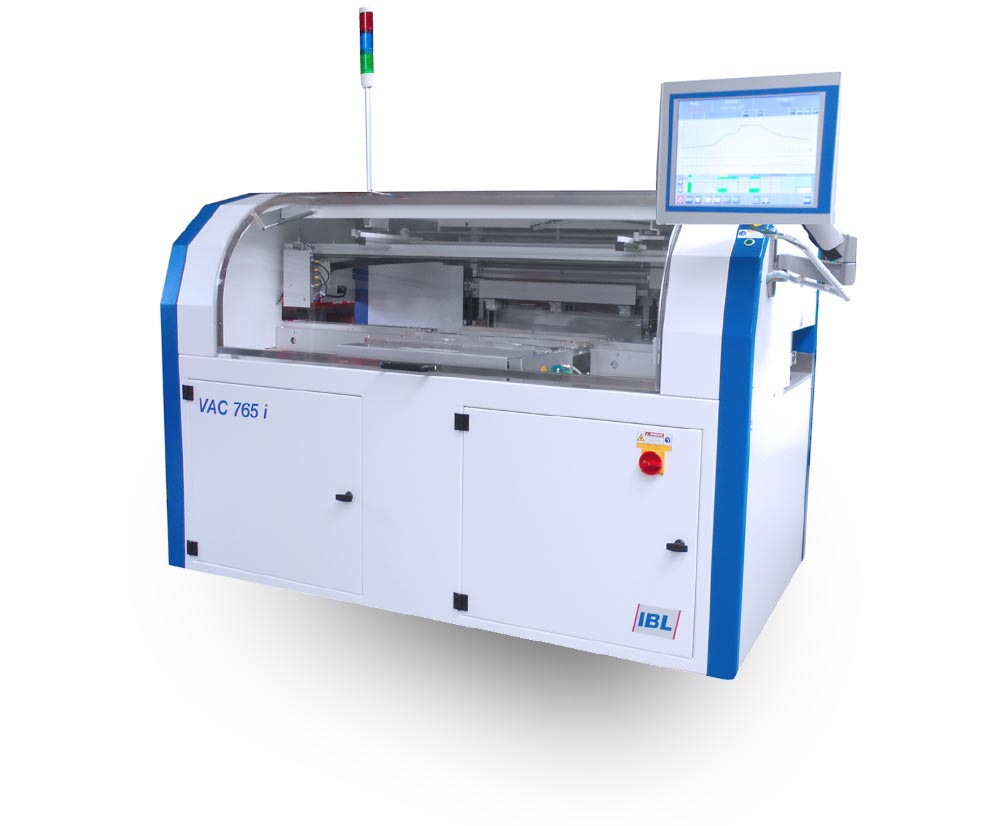

Brand: IBL, Germany

VAC745/765

- Combines the advantages of the vapor phase with the vacuum process and guarantees void-free solder joints with highest quality

- Wide variety of adjustable solder profiles

- Inert atmosphere during the whole reflow and vacuum process

- Low medium consumption due to 2-chamber design and medium recovery

- Temperature recording and profiling with 4 integrated channels

- Patented vacuum chamber inside of the process chamber

- Integrated fans with global bottom cooling

- Automatic monitoring of vacuum process

- Maintenance-free transport system (patented)

We’d love to help you boost your production efficiency.

Contact us.

_Specifications_

|

|

|

VAC745i |

|

VAC765i |

|

|

Max. board size Inline (in mm) |

|

630 x 400 x 50 mm (24.80 x 15.75 x 1.97”) with vacuum 630 x 400 x 60 mm (24.80 x 15.75 x 2.36”) without vacuum |

|

||

|

L x D x H |

|

2040 mm x 3040 mm x 1470 mm |

|

2040 mm x 3450 mm x 1470 mm |

|

|

Max. load on single carrier |

|

7 kg (15.43 lbs) |

|

||

|

Weight |

|

1290 kg (2843.96 lbs) |

|

1450 kg (3196.70 lbs) |

|

|

Max. board size batch (in mm) |

|

635 x 444 x 70 (25.00 x 17.48 x 2.76”) with vacuum 635 x 444 x 80 mm (25.00 x 17.48 x 3.15”) without vacuum |

|

635 x 644 x 70 mm (25.00 x 35.35 x 2.76”) with vacuum 635 x 644 x 80 mm (25.00 x 25.35 x 3.15”) without vacuum |

|

|

Liquid agent filling |

|

40 kg |

|

60 kg |

|

|

Water connection |

|

½“ / 2,5 – 5 bar |

|

||

|

Max. heating capacity |

|

10,4kW |

|

13 kW |

|

|

Average power consumption |

|

5,5 kW/h |

|

5,8 kW/h |

|

|

External vacuum module |

|

910 x 550 x 650mm (35.83 x 21.65 x 25.59“); 119 kg (262.35 lbs) |

|

||