V-Sky Soft

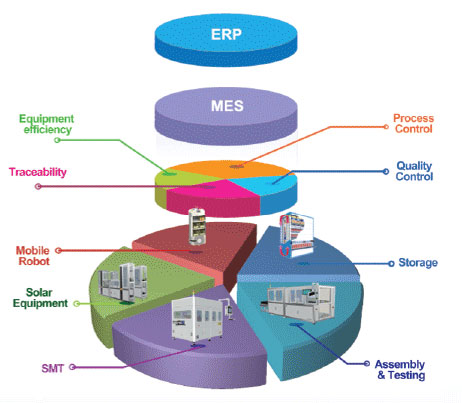

SMT Industry MES

Including warehouse management, production management, quality control and other modules.

Warehouse management:

- enables your material registration to be completed in less than a second

- Location management, first-in-first-out control

- Humidity sensor management

- Provide automatic component material tower solution (hardware + MES control, display automatic storage of materials, effectively save space and reduce labour costs)

- Provide intelligent robot solution (hardware + MES management, achieve JIT feeding, achieve lean production)

We’d love to help you boost your production efficiency.

Contact us.

Smart Warehouse

Intelligent Warehouse Management:

- Comprehensive material management and enhanced ERP

- Real-time feedback inventory

- Warehouse and interaction with the shop, automatic lean material requirements

- The combination of robot and material tower makes distribution more automated

Characteristic:

- Ability to maintain near-perfect inventory accuracy

- Automated logistics displayed on mobile terminals

- Advanced pull material logic operation

- Real-time material consumption information

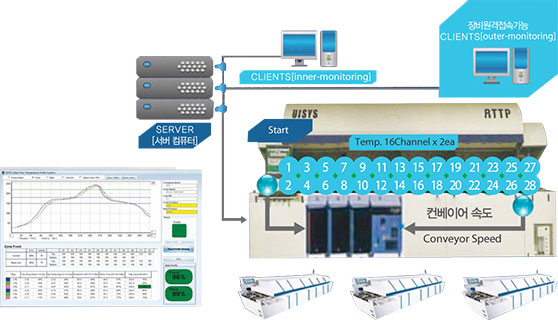

Model: UI-501

(RTTPS-REFLOW)

The system uses max. 32 channels temperature sensor fixed within the Reflow to detect any temperature changes and evaluate its real time status, while proximity sensors and photo sensors measures and monitors production environment of the conveyor belts and PCB thus enhancing productivity and preventing mass defects.

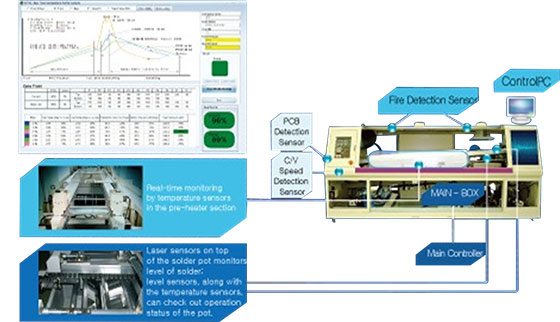

Model: UI-510

(RTTPS-WAVE)

The UI-510 RTTPS enables automatic profile by monitoring real-time temperature changes within the preheaters and solder pot/coolers, by fixing temperature sensors inside the wave machines. Proximity and impeller sensors enable changes in conveyor and motor speed, along with dip time, to improve productivity and preventing mass defects.

Model: UI-701

(RPPM)

UI-701 can realize profile automation by monitoring real-time oxygen distribution within equipment by fixing multi-channel suction points in the reflow machine, thus acquiring more than 30 profiles per day by checking continuous oxygen changes, along with enhanced productivity and prevention of mass defects.

We’d love to help you boost your production efficiency.

Contact us.

_Specifications_

| Specification | Minimum Requirement | |||||

| OS | Windows 8 | |||||

| Processor/Memory | Pentium2 and later / 64MB and more | |||||

| HDD / CD-ROM | 64MB and more / CD-ROM (Program Installation) | |||||

| Video Card / Connection | 1024X768, 16 bit and more / RS232C | |||||

MES Smart Factory Automation solutions are at the forefront of Industry 4.0, enabling you to transform your manufacturing processes into highly efficient, interconnected, and intelligent systems. By harnessing the power of advanced technologies such as IoT, AI, and data analytics, our smart factory automation solutions optimize production, enhance decision-making, and drive operational excellence.

Our smart factory automation systems leverage real-time data collection and analysis to provide valuable insights into your production line, enabling you to monitor and control every aspect of your operations.

From machine monitoring and predictive maintenance to inventory management and quality control, our MES solutions integrate seamlessly with your existing infrastructure to streamline processes and maximize productivity. Experience the benefits of a connected and intelligent manufacturing environment with our smart factory automation machines and solutions.