Brand: Pulstec, Japan

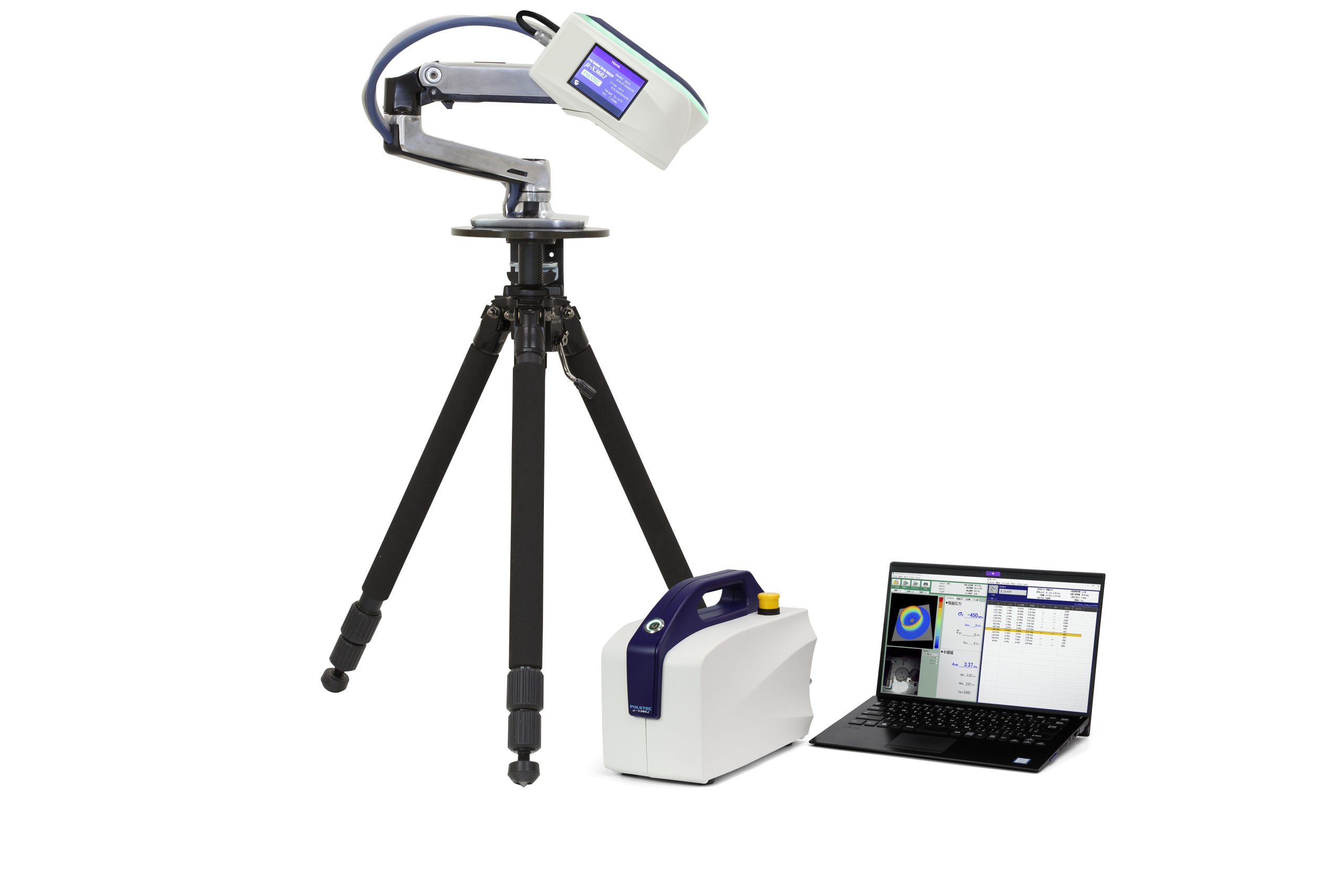

μ-X360J Portable X-ray Residual Stress Analyzer

The μ-X360J is the world’s lightest and smallest residual stress analyser. It’s a non-destructive measurement system for metals to obtain the residual stress, retained austenite and FWHM data based on X-ray diffraction technique.

Features:

- Non-destructive testing on gears, springs, bearings, crankshafts, shot peened samples and additive manufacturing.

- Uses the cos α technique with a single X-ray exposure and a 2D high-sensitivity detector for accurate measurements.

- Measurement items: Residual stress, Full Width at Half Maximum (FWHM) and retained austenite.

- Full diffraction rings can be obtained on two-dimensional detector.

- Displays crystal structure information, including large crystal grains and crystal orientation.

- Low power X-ray output (30 kV, 1.5 mA).

- Easy set up and simple operation.

- Easy and fast X-ray tube exchange compatible with various targets such as Cr, V, Cu, Co and Mn for broader material testing.

- Easy to carry and measure in the field because of its portability.

We’d love to help you boost your production efficiency. Contact us.

Applications :

- Various industrial fields such as transportation equipment (railways, cars, ships, airplanes, etc.), bearings, iron and steel structure and components, electric power, heavy machines, surface modification, etc.

- Widely adopted by domestic/overseas universities and public research institutions.

- Addresses issues like dimensional change post-machining, cracks/fissures of weld zones, cracks after heat treatment, strength shortage after treatment, etc.

- Process improvements, quality control, yield improvement, equipment durability check, remaining life assessment of infrastructure, etc.

_Specifications_

| Measurement items | Residual stress, FWHM(included with software), Retained austenite(Option) |

| Measurement method | cos α method(Single-incident angle method) |

| Collimator size | Standard: φ1.0mm(Irradiation size Approx. φ2mm) |

| X-ray tube cooling method | Air cooling |

| Power | AC100-240V, 50/60Hz, 130W |

Options

X-ray Safety Cabinet

This safety cabinet with interlock protection is designed to protect users from X-ray exposure; cabinet leakage less than 0.1μSv/hour.

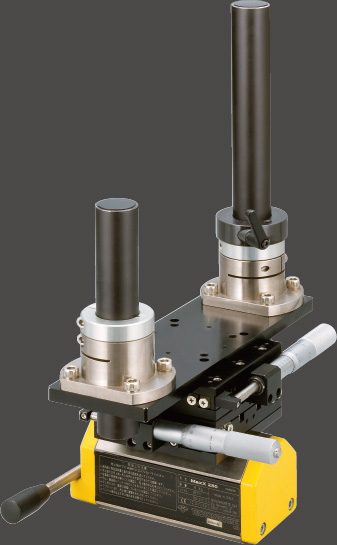

Electrochemical Polisher

This electrochemical polisher for the controlled removal of the metal surface layers without having minimal impact on the stress. Use this equipment when you need to measure the residual stress in the depth direction, not only the surface.

Flexible Arm with Magnet Stand

Since the bottom face of the stand is strongly magnetic, it is easy to adjust the sensor unit position with flexible arm. Both X and Y axis are adjustable in a 50mm range in steps with 0.01mm resolution.

Hand-carry Case

This hand-carry case can contains the complete standard set of the unit for the measurement.