Brand: INOTIS, Korea

PCB SCREEN PRINTER

- Used in SMT lines after AOI, separates NG PCBs.

- Motorised 3 stage Conveyor system ensures a reduction in the waiting time for PCB transfer

- PCB Push-Down Unit is used for big size PCB to prevent warpage

- RPSS Control which displays & controls real-time pressure for squeegees

- Built-in MES and Barcode Port

- Built-in Cp, Cpk Generator

- Suitable design for BTB Layout

We’d love to help you boost your production efficiency. Contact us.

_Specifications_

| ITEM | Model | |||

| X5L | X6L | X8L | ||

| Metal Mask | rame Size | 650*550mm | 650*550mm | 1000*1000mm |

| 736*736mm | 736*736mm | |||

| Print Origin | Center | |||

|

PCBA | Min Size | 50*50mm | ||

| Max Size | 510*510mm | 610*510mm | 800*400mm | |

| Thickness | 0.4 – 6.0mm | |||

| Weight | Max 3.0Kg | Max 4.0Kg | Max 5.0Kg | |

|

Conveyor | Pass Line | 920±30mm | ||

| Stage | Single Stage | |||

| Belts | Flat Belts(Anti-Static) | Time Belts | ||

| Clearance | Less Than 5.0mm both side | |||

| Components | +20mm / -20mm | |||

| Clamping | Edge / Vacuum Chamber / Multi-Point Clamp / Top Clamp | |||

| Width Adjust | Motorized Width Adjustment | |||

| Cycle Time | PCB Moving | 7.5 Sec | 8.5 Sec | 10.5 Sec |

| Model Change | Less Than 10 min | |||

| Accuracy | Repeatability | ±15 um | ||

| Squeegee | Material | Metal / Urethane | ||

| Direction | Front <-> Rear | |||

| Interface | SMEMA | |||

| Power | 1Ø 200-230(VAC), 50/60(Hz), Less Than 2.0 KVA | |||

| Pneumatic | 5-6 (bars) , 10Ø Air-hose,Max 150 l/min | |||

| Dimension | W*D*H | 1428*1394*1548 | 1600*1530*1548 | 1750*1530*1548 |

| Weight | Approx | 950 Kg | 1000 Kg | 1100 Kg |

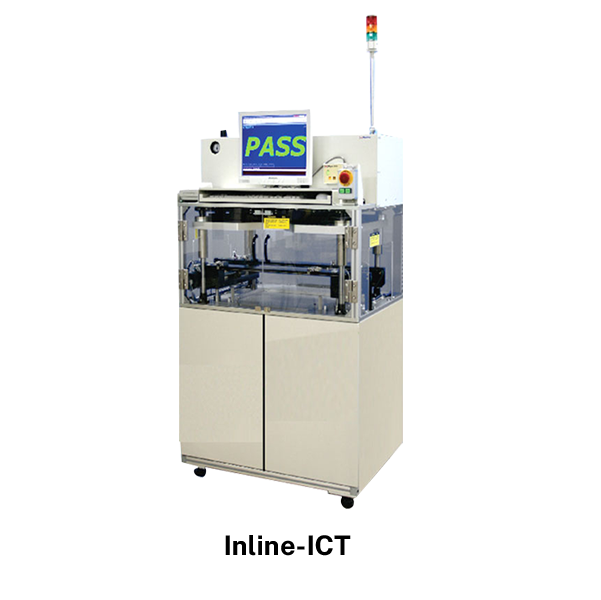

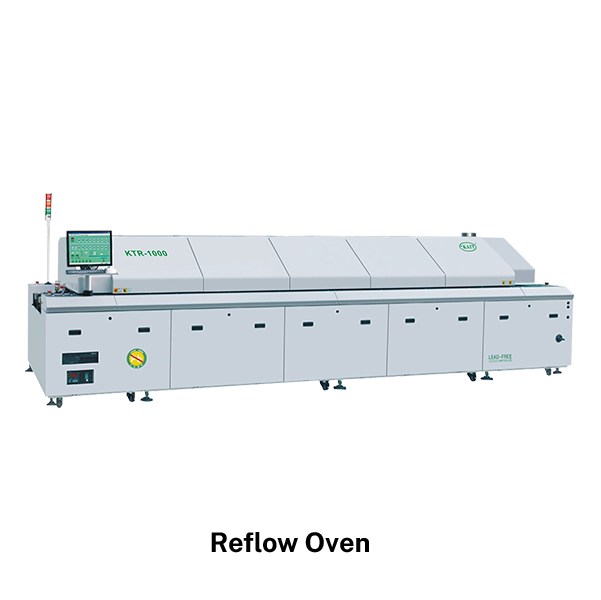

Similar Products

_SMT Line Solutions_

High-Precision PCB Printing Solutions for Superior Manufacturing

Precision and accuracy are crucial in producing high-quality printed circuit boards (PCBs). At Kyoritsu Electric India, we provide advanced PCB printing machines designed to meet the rigorous demands of modern electronics manufacturing. Our PCB screen printing machines ensure exceptional printing accuracy and reliability, making them the perfect choice for high-performance PCB production.

Kyoritsu’s PCB screen printers utilize cutting-edge technology to deliver consistent and precise printing results. Equipped with advanced features such as automatic stencil alignment, adjustable squeegee pressure, and precise control systems, our machines are ideal for even the most complex PCB designs.

One of our key offerings is our automatic PCB screen printing machine, designed to enhance efficiency and productivity. This automated solution eliminates manual intervention, enabling continuous and uninterrupted printing operations. By integrating an automatic PCB board printing machine into your production line, you can reduce labor costs, increase throughput and maintain consistent quality.

Additionally, we offer comprehensive technical support and maintenance services to ensure your circuit board screen printer machine operates at peak performance, minimizing downtime and maximizing efficiency.

Upgrade your PCB production process with our high-precision PCB screen printing machines, ensuring superior printing quality, enhanced productivity and seamless integration into your manufacturing workflow.