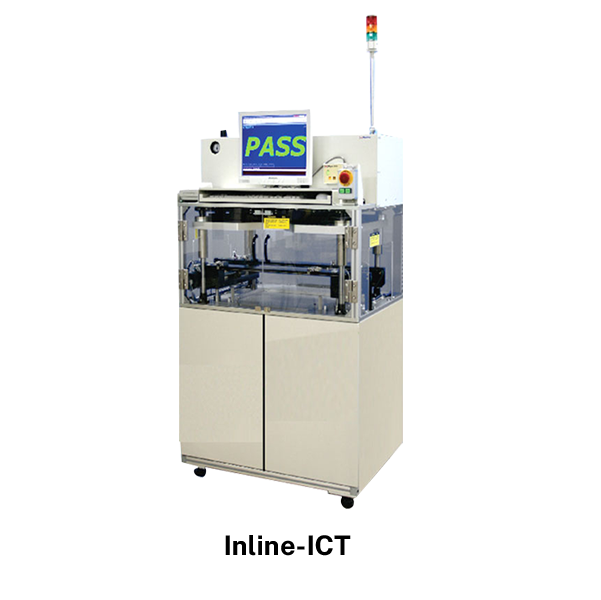

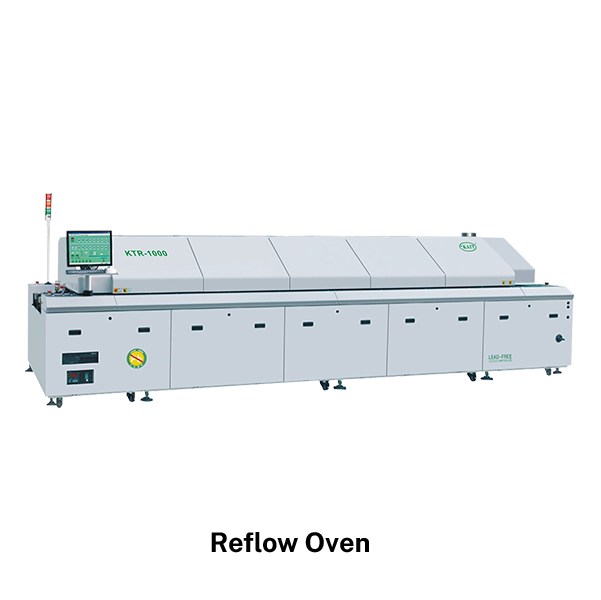

PCB HANDLING EQUIPMENT

We’d love to help you boost your production efficiency. Contact us.

Similar Products

_SMT Line Solutions_

Efficient PCB Handling Solutions for Seamless Electronics Manufacturing

In the fast-evolving world of electronics manufacturing, proper PCB management is crucial for ensuring smooth production and preventing damage. We offer a comprehensive range of PCB handling equipment designed to meet industry demands with precision and reliability. Our board handling equipment provides efficient and dependable solutions for handling PCBs at every stage of the manufacturing process, from loading and unloading to conveying and inspection.

Kyoritsu’s advanced PCB handling system is engineered to minimize the risk of damage to delicate components while optimizing production efficiency. Whether you require automated loaders, unloaders, conveyors, or specialized handling systems, we have the ideal PCB board handling solution to streamline your operations.

One of our key offerings is our PCB handling conveyors, designed to provide a seamless and automated transfer of PCBs between different production stages. These conveyors feature adjustable width, variable speed control, and gentle handling mechanisms to ensure the safe and efficient movement of PCBs. Designed for seamless integration into existing production lines, our conveyors help optimize workflow while reducing manual handling.

Enhance your electronics manufacturing efficiency with our cutting-edge PCB handling equipment, ensuring smooth operations, minimized downtime, and the highest protection for your valuable PCBs.