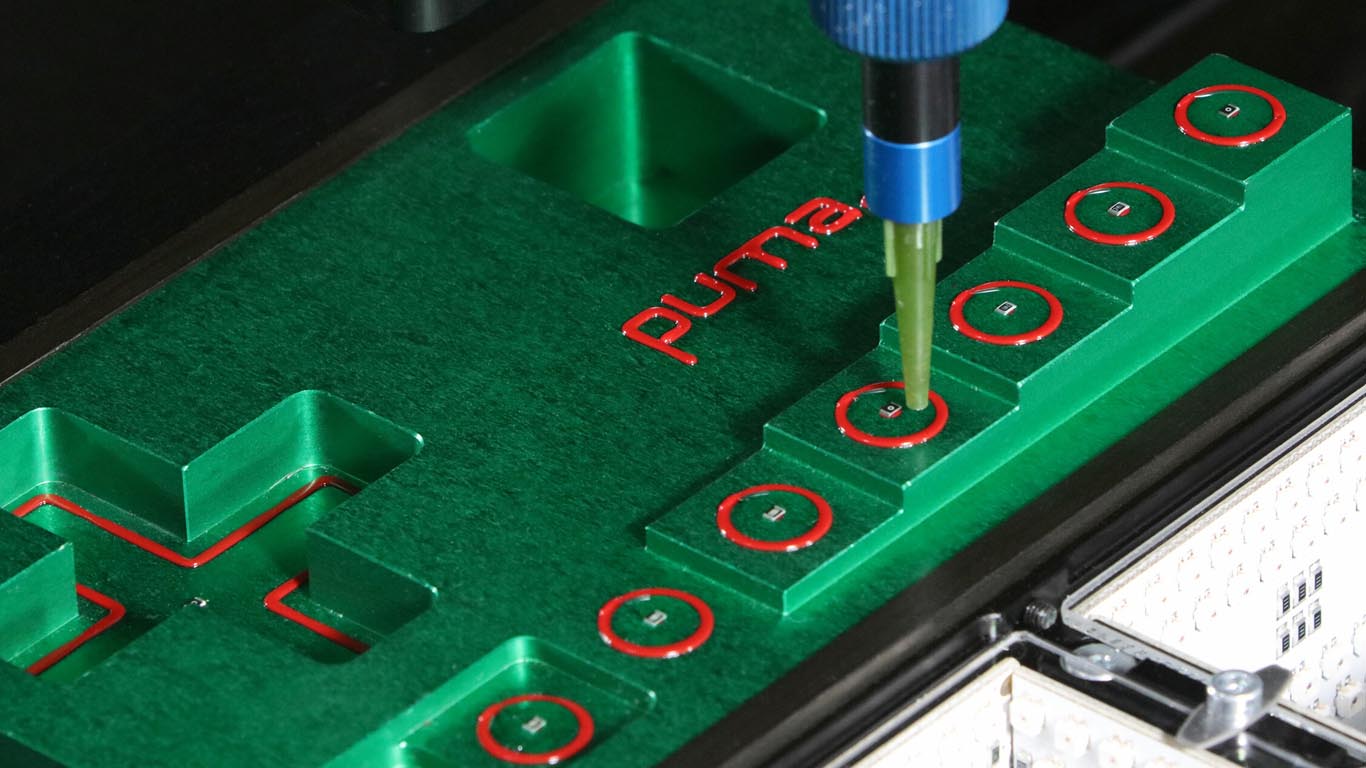

Brand: Essemtec, PUMA, Switzerland AG

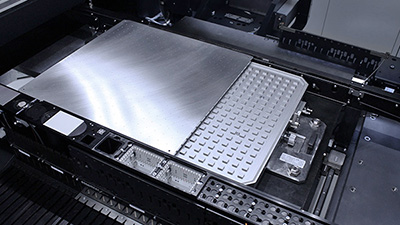

PICK & PLACE AND JET DISPENSING

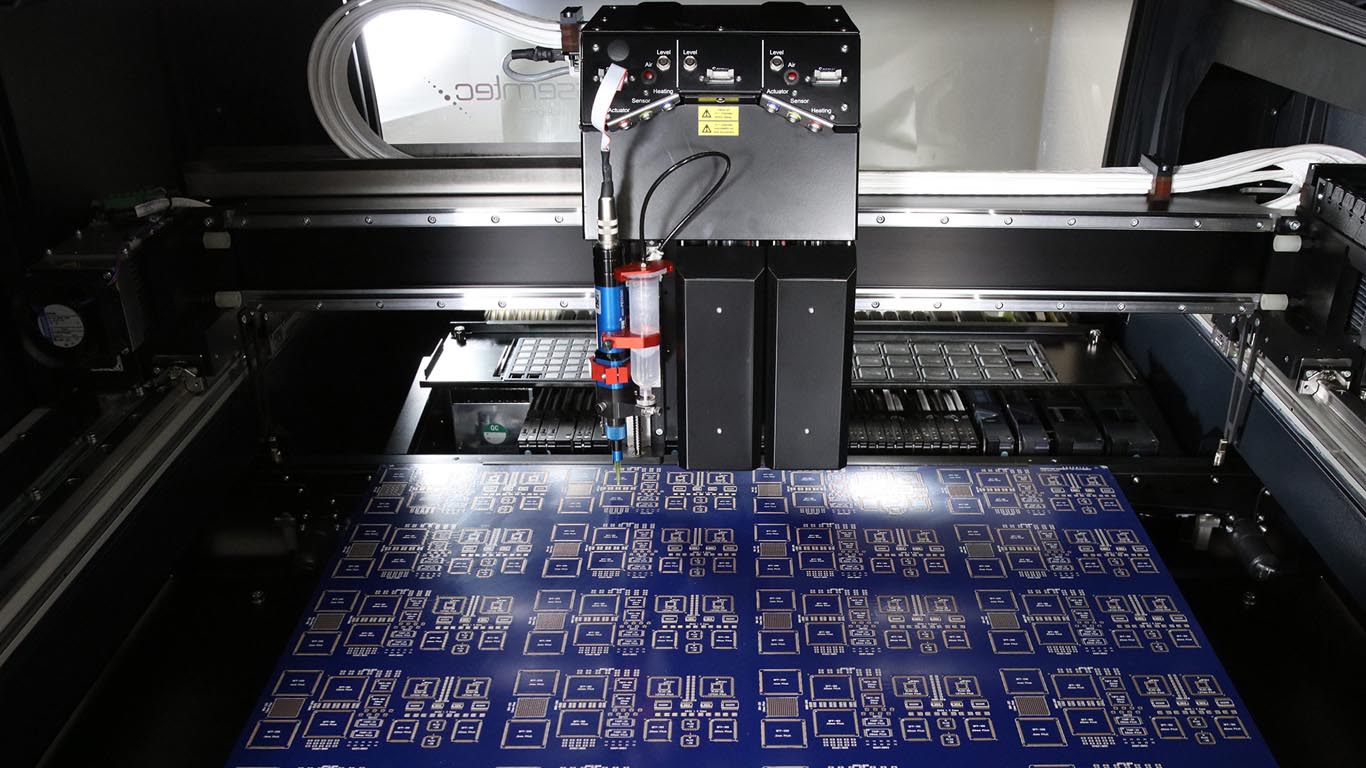

Introducing - The Puma - State of the art technology. Expandable in any direction. Same as in nature our Puma is common modular and adaptive in all kinds of environment. With different modules the systems grow synchronously with the customer’s requirements for performance and processes. Puma is world's best highspeed Pick-and-Place solution which can also be used in ultraflexible, rapid prototyping development.

Combined Process

- Highspeed placement and dispensing in single pass-through

- 1, 2 or 4 placement-axes and 1-2 dispense processes

Productivity

- Optimum 30’000 cph, up to 90’000 cph in line

- Valve performance 1’100’000 - System Ø 350’000 dots/h

Small Footprint

Up to 280 Feeder on 2 m2 (up to 420 in line)

- PCB size 560 x 610 mm, optional 1’800 x 610 mm

Mineral Cast

- No vibration, symmetrical mineral casting

- No warpage, no thermal drift

Quick Changeover

- Nonstop production, intelligent smart feeder

- Nonstop feeder and production changeover

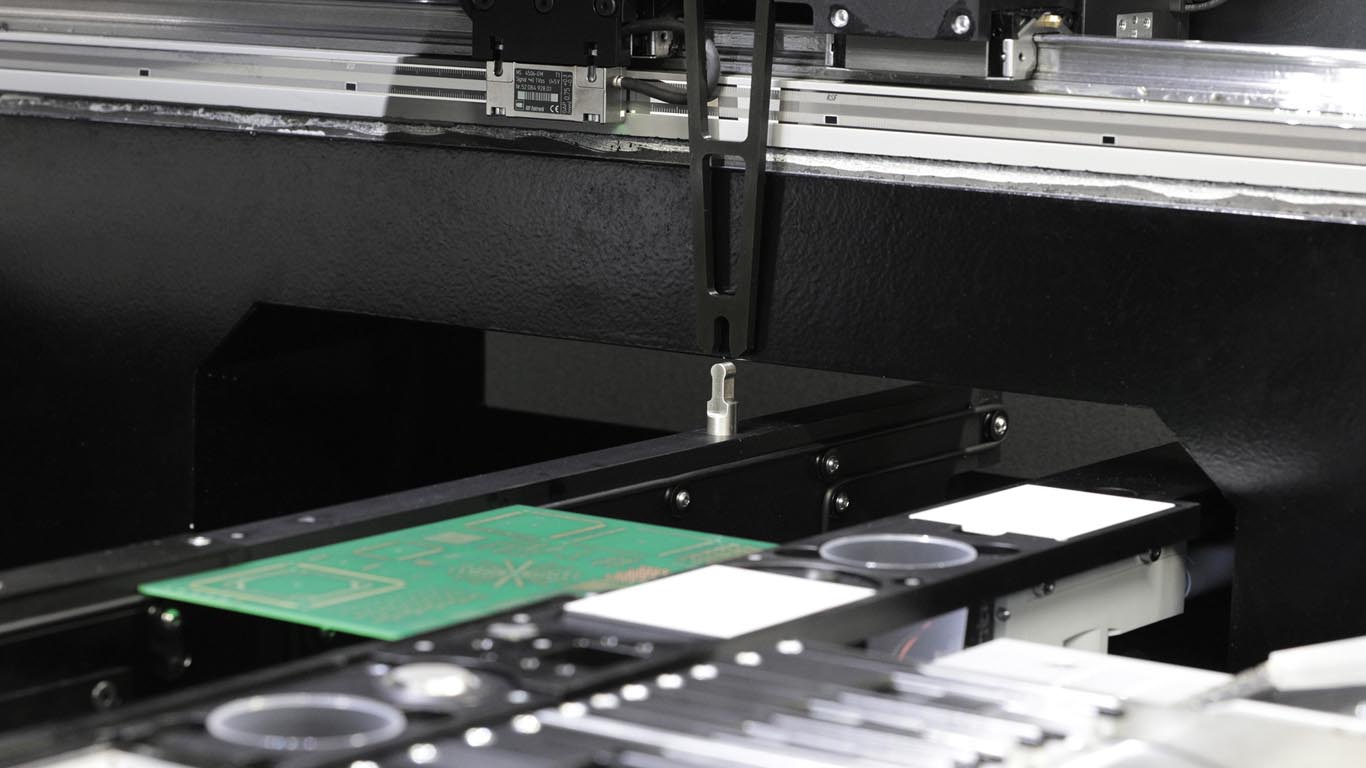

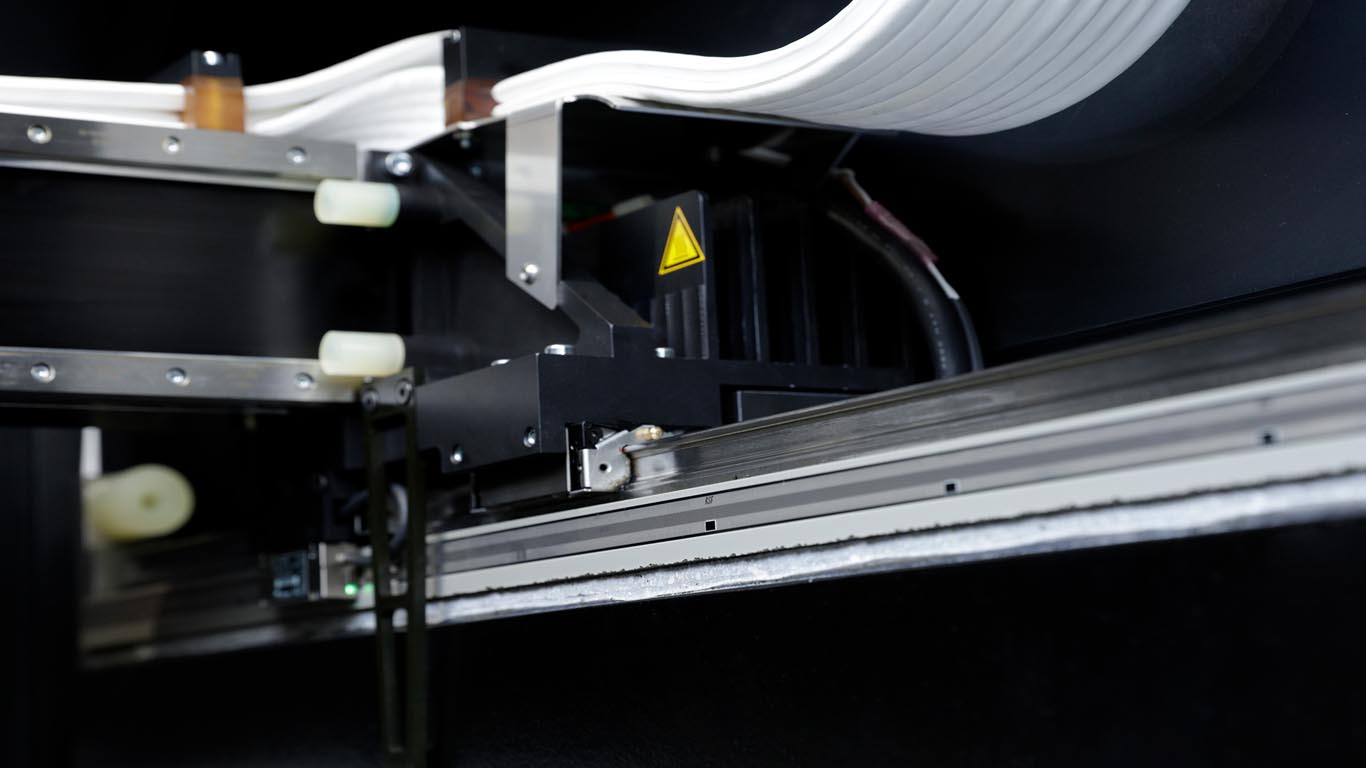

Linear Motors

- Fast, reliable double drive linear motors

- No maintenance, longest lifetime

Essemtec Puma SMT Pick & Place Machine

_Specifications_

| Puma4 | Puma2 | Puma | ||

|---|---|---|---|---|

| Productivity | Optimum placement speed | 30’000 cph (4-axes) | 17’400 cph (2-axes) | 9’000 cph (1-axis) |

| Solder Paste Jetting Shockwave Jet Valve Jet-on-the-Fly |

Max Frequency: 1’100’000 dots/h BGA Pattern Speed: 665’000 dots/h Average board speed: 350’000 dots/h |

|||

| Feeder | Feeder capacity 8 mm Tape | 280 (160 inline) | 260 (140 inline) | 260 (140 inline) |

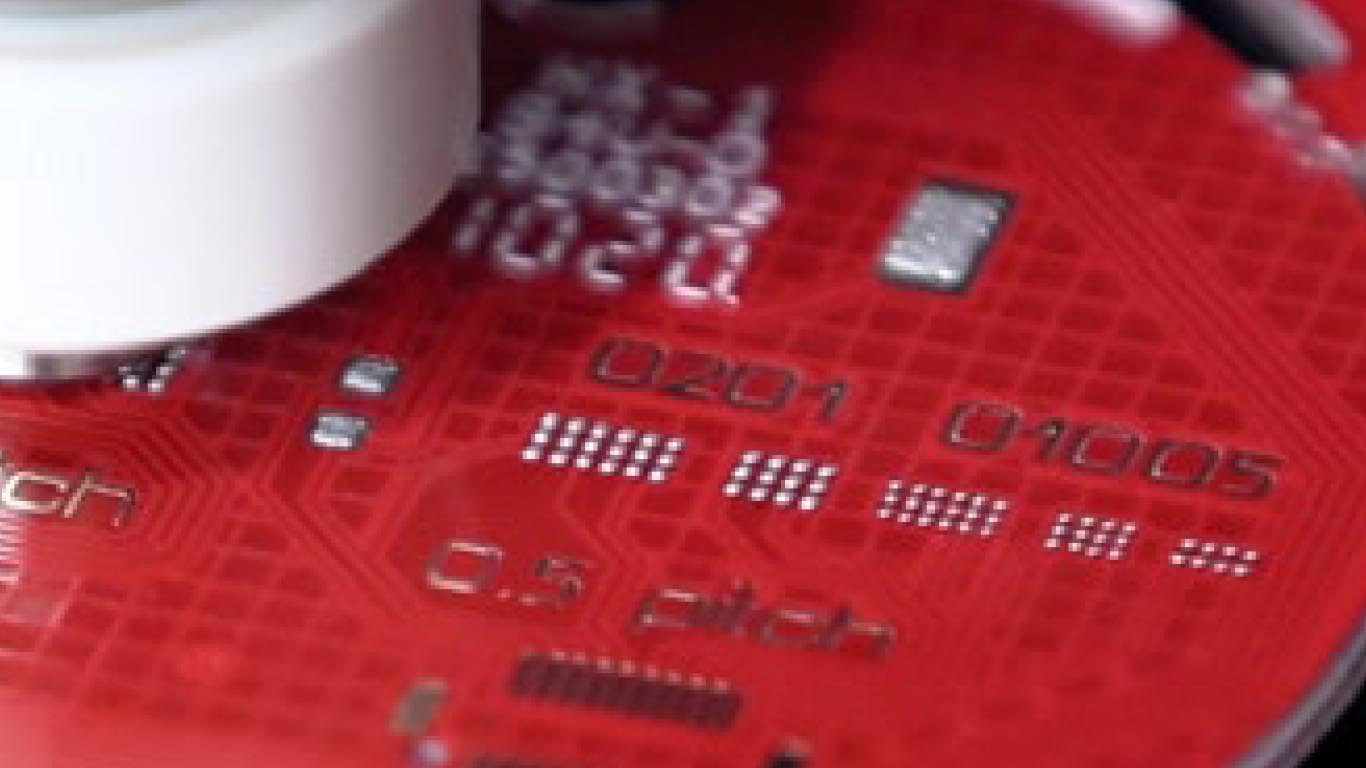

| Components | Component size range | 008004 (imp.) - 109 x 87 mm (Note specs for details) | ||

| Accuracy | Placement accuracy (x, y) | Chip ± 40 μm (3σ) / QFP ± 30 μm (3σ) | ||

| PCB | Max. PCB dimensions | 560 x 610 mm (22 x 24“) optional 1’800 x 610 mm (71 x 24“) | ||

| Dimensions | Machine footprint | 1’557 x 1’357 mm (61 x 53“) |

We’d love to help you boost your production efficiency.

Contact us.

A World of Benefits From NPI to High Flex, High Speed Production

Full operator support - Automated error analysis & KPI. Training, support and troubleshooting via advanced remote access. Investment protection; all options and heads retrofittable. Machine expansion in any direction.

Multi flexible feeder, multi lane cassette or highly accurate single lane feeder. Tape, Stick, Strip, Palettes and Tray slider. Largest component spectrum; 008004 (imp.) up to 80 x 80 mm, component height up to 25 mm.

Configurable heads with 1-4 placement-axis. 2,5D and 3D dispensing and jetting, High resolution digital Cognex vision system with auto component teach-in and irregular ball recognition.

Multitalent Software At Your Fingertips

State of the art, full graphics, 21.5”, 16:9 HD wide touch screen, fingertip operation, universal CAD conversion, zoom at camera windows, all-in-one job planning, setup optimisation, stock management, ERP/MES connection, data analysis, line management and more.

Modularity

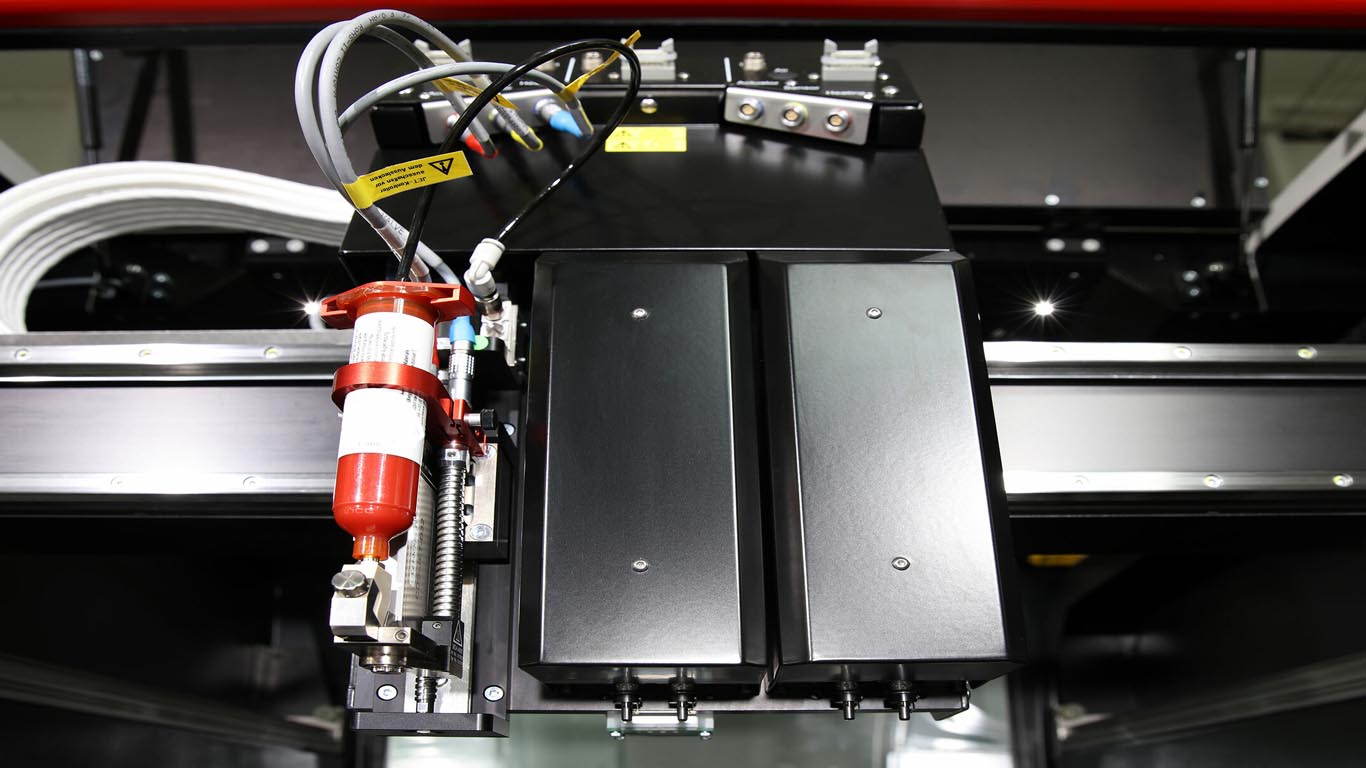

Valves and Pumps

| Piezo Jet | Shockwave Jet | Volume | Screw | Time-Pressure |

|---|---|---|---|---|

| SMD-Adhesives, Underfill, Silver Epoxy, UV-Adhesives, Globe Top, Encapsulation, Dielectric Ink |

Solder Paste, Liquid Metal |

Underfill, Gasketing, Globe Top, Dam and Fill, Solder Paste |

Solder Paste, SMD-Adhesive, Globe Top, Encapsulation, Silver Epoxy, Dam and Fill |

Gasketing, Globe Top, Encapsulation, Solder Paste, SMD-Adhesive, Silver Epoxy, Dam and Fill |

| Low - High Viscosity | High Viscosity | Low - High Viscosity | High Viscosity | High Viscosity |

| Max Frequency: 2’000’000 dots/h BGA Jet-on-the-Fly: 780’000 dots/h BGA Stop & Jet: 177’000 dots/h |

Max Frequency: 1’100’000 dots/h BGA Jet-on-the-Fly: 665’000 dots/h Average Speed: 350’000 dots/h |

26’000 dots/h (BGA Pattern*) |

30’000 dots/h (BGA Pattern*) |

38’000 dots/h (BGA Pattern*) |

Optional Equipment For our Pick-and-Place